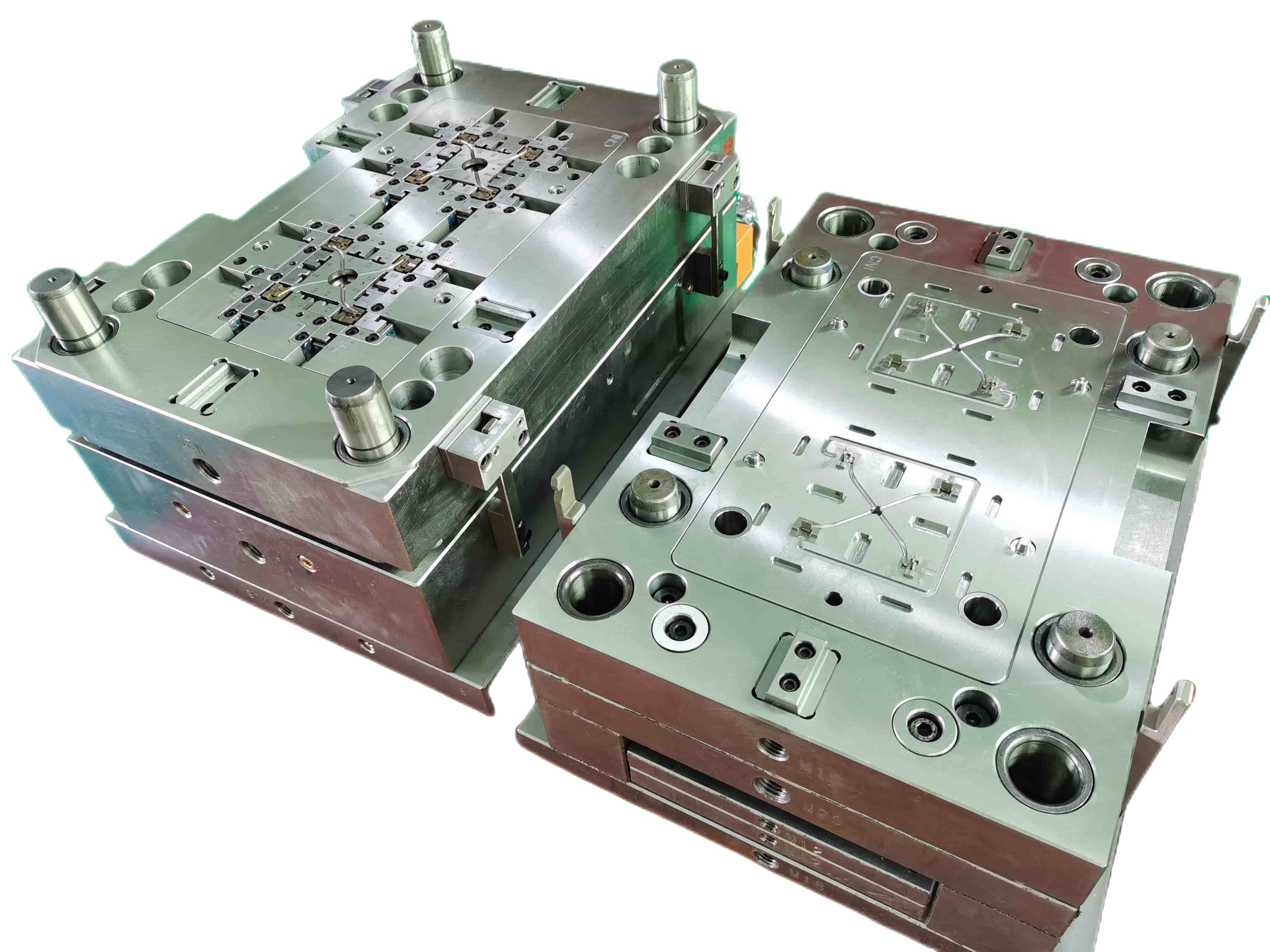

| Appliance and Type | Electronic precision components made by multi cavity plastic injection mould, | |||||

| Part name | Mobile connector | |||||

| Resin | Powder metallurgy materials | |||||

| No. of cavity | 1*8 | |||||

| Mould Base | S50C | |||||

| Steel of cavity&Core | S136 HRC 52-54 | |||||

| Tool weight | 450KG | |||||

| Tool size | 450X350X370mm | |||||

| Press Ton | 90T | |||||

| Mold life | 1000000 shots | |||||

| Injection system | Hot runner, 2pcs Mold-master hot tips | |||||

| Cooling system | Cooling by oil, mould temperature 120 degree | |||||

| Ejection System | Two step ejection | |||||

| Special points | Powder metallurgy materials, precision injection mould, hot runner, 8 cavity mould, short cycle time | |||||

| Difficulties | High precision tolerance,high temperature mould,short mould making lead time and very short moulding cycle time. The material is Powder metallurgy material having short cooling time and high demand of injection machines. | |||||

| Lead time | 4 weeks | |||||

| Package | Mould stay in China for plastic moulding production | |||||

| Packing items | Certification of steel, final 2D & 3D tool design, hot runner document, spare parts and electrodes… | |||||

| Shrinkage | 1.005 | |||||

| Surface finish | SPI B-1 | |||||

| Injection moulding cycle time | 9 seconds | |||||

| Second treatment of products after moulding | Heat treatment for molded products | |||||

| Export to | Mould stay in China for plastic moulding production | |||||

The difficulties

High precision tolerance,high temperature mould,short mould making lead time and very short moulding cycle time.

The material is Powder metallurgy material having short cooling time and high demand of injection machines.

What is powder metallurgy?

Powder metallurgy is a manufacturing process that utilizes pressurized compaction and sintering of metal particles to create a variety of parts and components. The process involves blending together powdered metals such as iron, aluminum, bronze, stainless steel and cobalt with lubricants and binding agents before subjecting them to high levels of pressure. The resulting mixture is then heated until the materials chemically fuse together, creating parts that are much stronger than traditional casted or machined components.

Due to its versatility, powder metallurgy has become increasingly popular for the production of complex parts used in automotive, aerospace and consumer electronic applications.

What is high temperature mold?

High-temperature molding is a type of injection molding process that utilizes elevated temperatures and pressures to produce parts with high strength and durability. The process works by heating raw thermoplastic material until it is molten and then injecting it into an enclosed mold where it is held in place under pressure. Heat from the molten resin combined with pressure causes the material to form into the desired shape before cooling. This process allows for the creation of complex parts that are resistant to extreme temperatures and corrosive chemicals, making them ideal for use in industries such as automotive, aerospace, medical devices and electronics.

Common Plastic Material includes: PEEK, PPSU, ULTEM® (Polyetherimide, PEI), Celazole®, Vespel®, Torlon® (Polyamide-imide) and so on.

Mold design for high temperature mold

When designing molds for high-temperature plastics it's important to include heat transfer channels as well as use thermal pins to ensure the plastic cools evenly during the injection molding process.

Additionally, selecting the right mold material is essential for creating parts that can withstand extreme temperatures without warping or cracking.

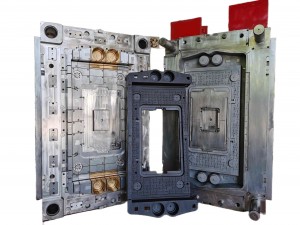

In this project, we used steel of S136 with HRC 52~54, the production volume is very high, 100000pcs parts were needed each day, so we used 8 cavity mold and make many copy ones to meet the quantity request. For cooling, it is cooled by oil and the mold temperature reach to 120 degree. The cycle time is 9 seconds and we used 2 step ejection for parts release. This part will be heat treated after molding.

The injection mould tool is 8 cavity high temperature injection mould.

Plastic is powder metallurgy materials and the molded parts will need heat treatment as it is the mobile connector.

Injection moulding cycle time is very short, 9 seconds for one shot.

We have made many copy tools for this customer. Our designers work very effective, for DFM, it is finished within 1 day, 2D layout within 2 days, and 3D within 3 days.

The mold manufacturing lead time is 4 weeks.

For mold design, when time is very urgent, we normally make 3D drawing directly after DFM, but of course, it must be based on customers' approval.

2D layout

3D mold design

3D mold design

FAQ

Our main business is for plastic injection mold making, die cast mold making, plastic injection molding, die casting (Aluminum), precision machining and rapid prototyping. We also provide value-added products including silicon parts, metal stamping parts, extrusion parts and stainle

No, we are a real mould manufacturing and plastic injection molding factory. We can provide registration image for reference and any other information you want if needed. Meanwhile, you can visit us anytime, even no appointments.

Suntime team provide 24/7 service working style. For Chinese public holidays, our sales and engineers can take overtime work for any of your emergency. And when there is necessary, we will do the best to ask workers to take overtime work during holidays by day shift and night shifts to meet your urgent requirements.

We have more than ten years exporting experience to global market ,exported plastic injection mould, die cast mould, die casting parts, plastic injection molded products and CNC machining components etc,.

For mold manufacturing, we have CNC, EDM, Grinding machines, milling machines, drilling machines, etc,. For custom plastic molding, we have 4 injection machines from 90 ton to 400 ton. For quality inspection, we have hexagon CMM, Projector, hardness tester, height gauge, vernier caliper and so on.

GET A FREE DFM TODAY!

-

Plastic injection moulding project from Rapid p...

-

Big size plastic injection mould for automotive...

-

High glass fiber Nylon material mold tooling fo...

-

Plastic tooling family mold automotive tail lig...

-

Injection multi cavity mould for caps of packa...

-

Plastic injection mould insert mold for Automo...