8 Year Exporter Telecommunications Metal Machining Parts - Plastic injection mould insert mold for Automotive battery industry – Suntime Detail:

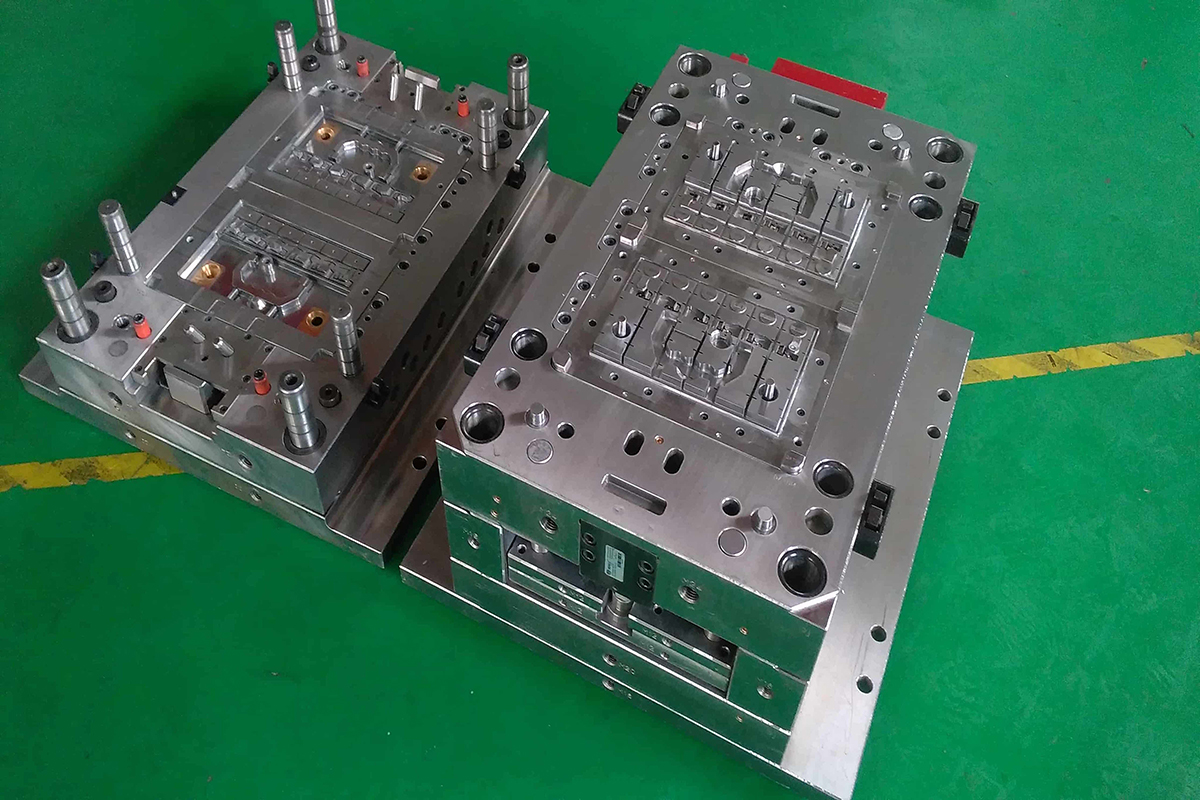

Suntime Precision Mould has made many similar battery lids and boxes with different size. The surface is A-3 polish. There are many ribs inside in the battery lid and need to do very well in mould cooling so that the warpage can be controlled great. This product is used for Automotive industry. End customer is very happy with our quality and service, Suntime had the opportunity to visit them twice before Covid-19.

| Appliance and Type | Automotive battery box and lid, plastic insert moulding | |||||

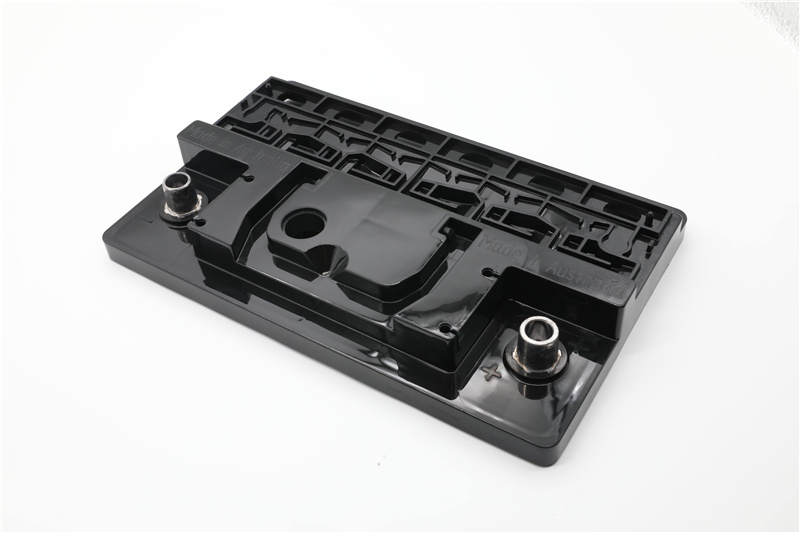

| Part name | Battery Lid | |||||

| Resin | PP | |||||

| No. of cavity | 1 Cavity and 2 cavities | |||||

| Mould Base | S50C | |||||

| Steel of cavity&Core | 738H | |||||

| Tool weight | 950 ~ 1450kg ( 10 sets moulds) | |||||

| Tool size | 450*600*500 ~ 450*800*500 | |||||

| Press Ton | 380 T | |||||

| Mold life | 500000 | |||||

| Injection system | Hot runner of mold master hot tips | |||||

| Cooling system | 25 ℃ | |||||

| Ejection System | Ejector pins | |||||

| Special points | A-3 polish,ultrasonic welding | |||||

| Difficulties | Warpage caused by different wall thickness | |||||

| Lead time | 4~5 weeks | |||||

| Package | Anti-rust Paper and film, little anti-rust oil and plywood box | |||||

| Packing items | Certification of steel, final 2D & 3D tool design, hot runner document, spare parts and electrodes… | |||||

| Shrinkage | ||||||

| Surface finish | Mirror polishing | |||||

| Trade terms | FOB Shenzhen | |||||

| Export to | Australia | |||||

Suntime has very effective mold designers. For DFM, it can be finished within 1~2 days, mold flow / 2D layout within 2~4 days, and 3D within 3~5 days depending on mold complexity.

2D Layout

3D mold design

3D mold design

Mold flow

Customers came to Suntime many times to check the tool making and moulding, and Suntime team has visited them twice in 2016 and 2019 before the Covid to provide technical support. After our customers’ introduction, Suntime team knew more about the the working process of automotive battery production. And we have more knowledge and confidence to do better for them based on our years’ experience.

* We used Becu for the lead post area for better cooling.

* One side of the parts is thin and another side is very thick, Suntime had to control very well for the molded part’s deformation.

* The battery lid is ultrasonic welding to battery box.

* We prepare spare parts every time before mold shipping.

1. Can we sign NDA Between Suntime Precision Mould?

Yes, we understand that all your design and information are confidential. It is absolutely no problem to sign a NDA before cooperation. And it is our obligation to protect your information unless having your approval to let the third party know.

2. Besides the battery box lid, do you also make battery box and handle?

Yes, we have much experience of this kind of battery box moulds with different sizes including battery lids, battery box and handles. The end customer is very happy with our quality and lead time.

3. This project is insert mold, what other types moulds you can make?

Normal cold runner & hot runner injection mold,Over mold, insert mold, family mold, multi-cavity mold (32 cavities), 2K mold, Auto unscrewing mold, high temperature mold, MUD mold, Rapid tooling and so on.

4. Who can speak good English in your company? How’s your communication?

“Our sales have good English not only in writing but also in oral speaking, you can contact us by any ways like email, SNS, phone calls, video meeting and visiting.

Our engineers not only have good experience in technical things, but also can read, write and speak some in English. You can communicate with them 1 to 1 directly. ”

5.How about the tolerance for parts made in Suntime Precision Mould?

Mold: +_0.01mm, Plastic Part: +_0.02mm and Machining product: +_0.005mm

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of 8 Year Exporter Telecommunications Metal Machining Parts - Plastic injection mould insert mold for Automotive battery industry – Suntime, The product will supply to all over the world, such as: Belarus, Finland, Paris, We are always creating new technology to streamline the production, and provide goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!

-

Factory Cheap Hot Die Cast Mold Factory - Plas...

-

Professional Design Supplier For Molding And To...

-

Super Purchasing for Pharmaceuticals Plastic In...

-

China Supplier Packaging And Containers Mold An...

-

Wholesale Price China China Cnc Machining Servi...

-

Cheapest Factory Battery Casing Custom Injectio...