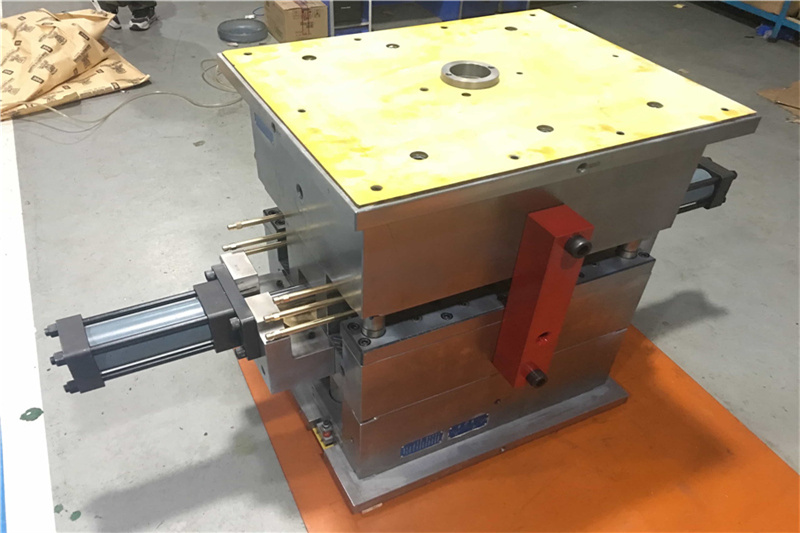

China wholesale Prototype Parts For Battery Casing - High glass fiber Nylon material mold tooling for Mining industry – Suntime Detail:

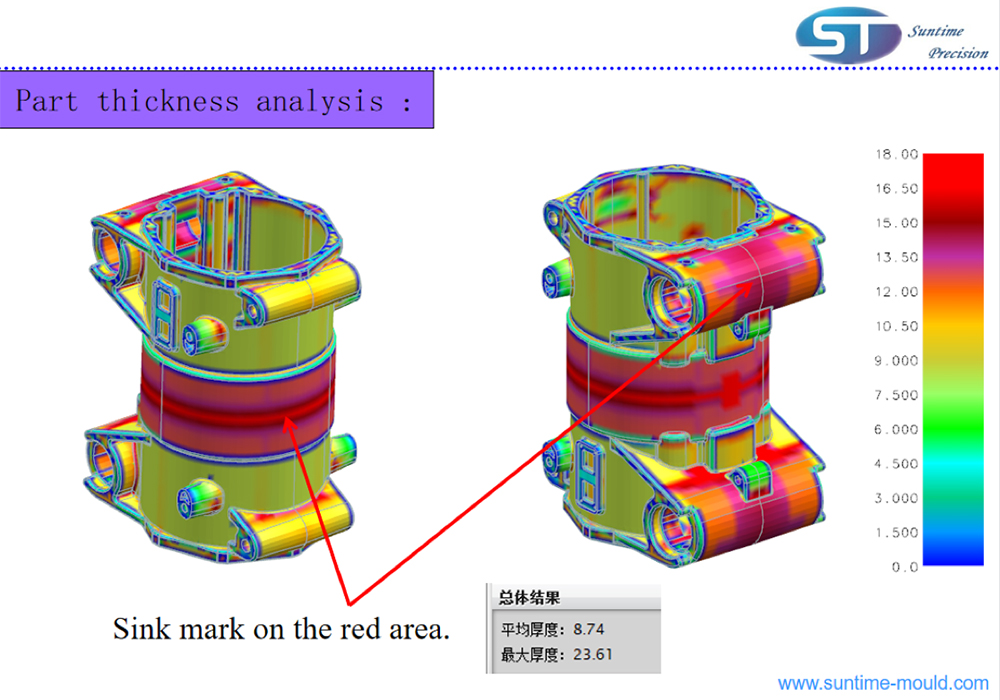

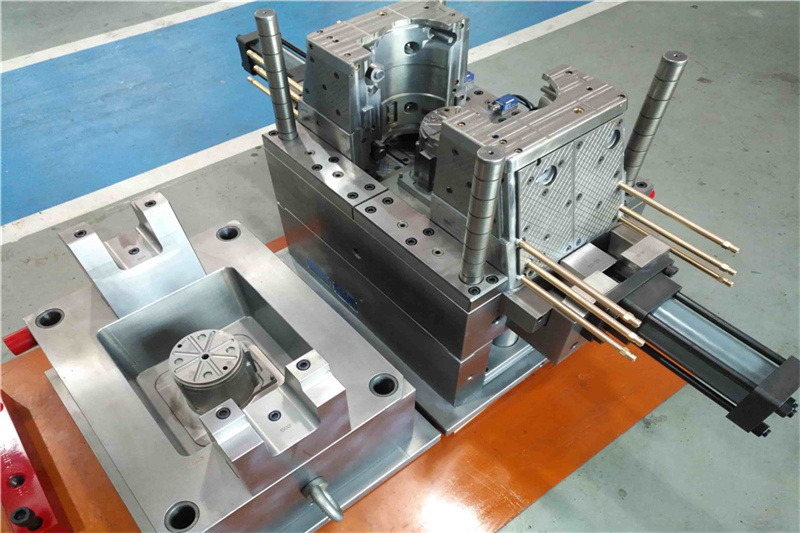

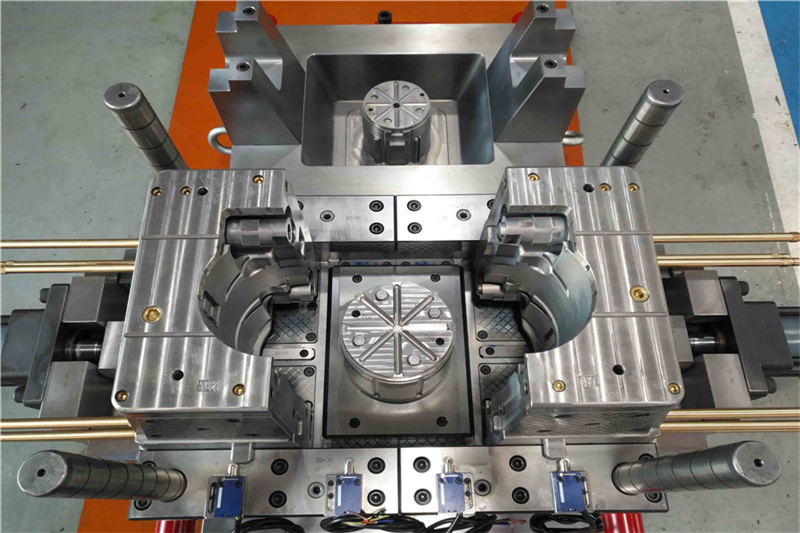

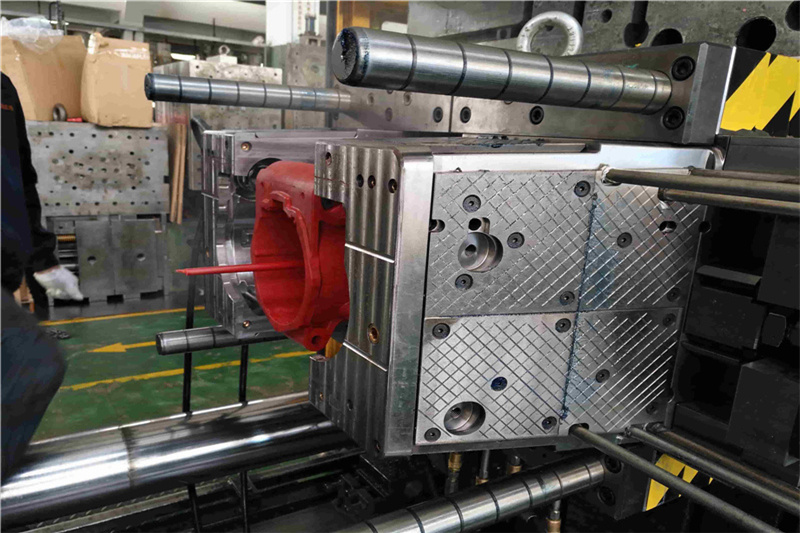

Plastic injection molded part. The product weight is around 4.8Kg, Nylon plastic with 45% Glass fiber. This plastic is very special, we used H13 hardened steel and asked for resin supplier help when doing the first mold trial. The wall thickness is not balance, Suntime designers made good mold cooling. There are two big sliders. Parts are expensive, use for wire pipe fitting in mine field.

| Appliance and Type | Mining Industry PA6+45GF Nylon with high glass fiber | |||||

| Part name | 3.3-425-04-03-005-A_B2B_RECEPTACLE_BODY_(MOULDED)(SINGLE-RACK) | |||||

| Resin | RTP 299 X 126459 Red | |||||

| No. of cavity | 1*1 | |||||

| Mould Base | LKM S50C | |||||

| Steel of cavity&Core | H-13 HRC48-50 /H-13 HRC50-52 | |||||

| Tool weight | 1979KG | |||||

| Tool size | 1544X876X649 | |||||

| Press Ton | 800T | |||||

| Mold life | 500000 | |||||

| Injection system | Cold runner mould 6PCS edge gate | |||||

| Cooling system | 130 ℃ | |||||

| Ejection System | Stripper plate | |||||

| Special points | Part weight is 4.8KG,material is PA6 + 45% GF. | |||||

| Difficulties | The mold steel and cooling are very important. Two big sliders. | |||||

| Lead time | 5.5 weeks | |||||

| Package | Anti-rust Paper and film, little anti-rust oil and plywood box | |||||

| Packing items | Certification of steel, final 2D & 3D tool design, hot runner document, spare parts and electrodes… | |||||

| Shrinkage | 1.003 | |||||

| Surface finish | B-2 | |||||

| Trade terms | FOB Shenzhen | |||||

| Export to | Australia | |||||

Suntime has very effective mold designers. For DFM, it can be finished within 1~2 days, 2D layout within 2~4 days, and 3D within 3~5 days depending on mold complexity. When time is very urgent, we normally make 3D drawing directly after DFM, but of course, it must be based on customers’ approval.

DFM Analysis

DFM Analysis

3D mold design

3D mold design

Customer say: ‘Thank you. The boss from XXX come to see us today, he said the samples are great. Very happy with service and said thank you to everyone. So, thank you from me Selena. ‘

Suntime precision mould has rich experience for Nylon with glass fiber material plastic mould from the start of company establishment. We also has made many products for Automotive industry and other industries.

1. What production material you usually use?

“For die casting, the aluminum material is A380.

For plastic injection molding, resin includes PEEK, PPSU,ABS, , PC, PC+ABS, PMMA, PP, HIPS, PE(HDPE,MDPE,LDPE). PA12, PA66, PA66+Glass fiber,TPE,TPR,TPU, PPSU, LCP, POM, PVDF, PET, PBT…”

2. Where are your customers located?

Our molds and parts are mainly for European countries, America and Australia such as Germany, UK, Portugal, Sweden, Norway, Denmark, USA, Canada, Mexico, Australia and so on.

3. What are the shipping terms?

We usually do Exwork and FOB shenzhen. But if customers require DAP, we also can do it.

4.. What kind of logistics/ shipping ways for transportation?

“a). Sea shipment(3~6 weeks)

b). Air shipment (3~10 days)

c). Train shipment (2~3 weeks)

d). Express (Fedex, UPS, TNT, DHL..)”

5. What services and products can you offer?

“Our main business is for plastic injection mold making, die cast mold making, plastic injection molding, die casting (Aluminum), precision machining and rapid prototyping.

We also provide value-added products including silicon parts, metal stamping parts, extrusion parts and stainless machines parts and so on.”

Product detail pictures:

Related Product Guide:

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for China wholesale Prototype Parts For Battery Casing - High glass fiber Nylon material mold tooling for Mining industry – Suntime, The product will supply to all over the world, such as: Mexico, Brisbane, Amsterdam, we've got all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!

-

Massive Selection for Custom Injection Molding ...

-

Factory made hot-sale Aluminum Die Casting Part...

-

Factory selling Custom Injection Molder And Man...

-

Super Lowest Price Telecommunications Plastic I...

-

Online Exporter Packaging And Containers Mouldi...

-

Factory wholesale Custom Injection Molder And M...