CNC (Computer Numerical Control) turning and milling machining is a manufacturing process that utilizes computer-controlled tools to shape materials like metal and plastic into desired shapes, sizes, and configurations by milling machines and turning machines (Lathe). With programming, CNC machines can shape metals and plastics more consistently than manual methods, which allows for greater accuracy. Additionally, CNC machining requires less time to create parts than traditional production processes such as grinding and hand cutting. With the help of CNC machines, we can quickly produce complex parts in high quantity with fewer defects repeatedly.

Materials commonly used for CNC machining applications include aluminum, brass, bronze, copper, stainless steel, titanium, and plastic.

Other materials used may include tool steels such as high speed steel and hardened steels, composites such as carbon fiber or Kevlar, wood and even human bone or teeth.

Each of these materials offer different properties which can be taken advantage of depending on the application.

Advantages

• Consistent production

CNC machining offers consistent and reliable production in the manufacturing industry. The automated process ensures consistent results with each product produced, making it ideal for achieving consistent quality over large quantity orders. With consistent production and fewer chances of errors, manufacturers have the potential to reduce lead times while anticipating demand accurately.

• Precise and high accuracy

CNC machining is superior to traditional machining processes. It is precise and highly accurate, meaning parts can be produced with precise specifications using fewer steps and materials. CNC machining also eliminates the need for manual labor by performing complex tasks such as drilling, milling and cutting without the need for human intervention. This reduces labor costs, decreases scrap rates and increases productivity since multiple parts can be run at once.

• Repeated production and less error

CNC machining has become increasingly popular in the manufacturing industry due its ability to repeatedly produce accurate results with less error than manual labour. After being programmed, operations can be reused repeatedly. Additionally, CNC machining produces consistent dimensions for precise assembly fitting, helping manufacturers secure streamlined processes and better end products.

• Variety of material options and less cost than toolmaking for low volume demands

Variety of materials can be used in CNC machining, including but not limited to metal, plastic, and wood. This variety of material options can be the best suited for customers’ needs.

Furthermore, CNC machining does not require special tooling or fixtures, making it a cost-effective alternative for mass production. But it is also an efficient production method, that allows manufacturers to complete large orders quickly and accurately.

Disadvantages

• The cost associated with setting up the machines for production can be high.

• If the wrong parameters are used during programming or setup, it can lead to costly mistakes in the finished product.

• The machines themselves require significant maintenance and repair costs over time as they age.

• CNC machining may not be suitable for low volume orders due to the set up costs involved.

Details costs associated with setting up CNC machines

Setting up CNC machines involves costs in a few different areas. Firstly, the cost of purchasing the machine itself can be quite high due to the complexity and accuracy outlined in designing and building the machinery. This cost will include software and programming costs as well, as these are needed to operate the machines. In addition, there may be training costs associated with getting staff up to speed on operating machines correctly and safely. Lastly, materials need to be purchased that are specifically designed for use with CNC machining which can add additional costs.

• CNC machining may not be suitable for low volume orders due to the set up costs involved.

For CNC machining projects, aluminum is typically the most cost-effective material to use.

This is because it is easy to machine and has a high strength-to-weight ratio.

Aluminum also has good thermal conductivity, which can help reduce energy costs during the machining process.

Additionally, aluminum has a relatively low melting point, which makes it ideal for high temperature processes like welding or brazing.

Lastly, aluminum is corrosion resistant and non-magnetic, making it suitable for a variety of CNC machining applications.

Aluminum offers many benefits when used for CNC machining projects. Some of these include:

• Cost-effectiveness: Aluminum is typically the most cost-effective material to use as it is easy to machine and has a high strength-to-weight ratio.

• Thermal Conductivity: Aluminum has good thermal conductivity, which can help reduce energy costs during the machining process.

• Low Melting Point: Aluminum's relatively low melting point makes it ideal for high temperature processes like welding or brazing.

• Non-magnetic & Corrosion Resistant: Aluminum is corrosion resistant and non-magnetic, making it suitable for a variety of CNC machining applications.

As an CNC Machining Supplier, we ensure 99% on-time delivery and the fastest machining time in just one day. We have minimum order quantity (MOQ) from even just 1PCS, making sure that all our customers get their desired products delivered at their doorstep. Our expert engineers follow up your projects in English directly so that you can have effective communication with us. That’s why when it comes to choosing a CNC machining supplier, SPM is your go-to choice.

• Our MOQ can be 1pcs, no matter how small your order quantity is, we always provide you the VIP service.

• For all your CNC turning & milling machined components, we can provide steel certificate, heat treatment certificate and SGS testing report if needed.

• Engineers communicate directly in English. Our engineers have many years experience in this filed, they check drawings very carefully and make sure every requests are fully understood before manufacturing.

• We promise, any quality issue caused by us, we will make new for free or take responsibility you required!

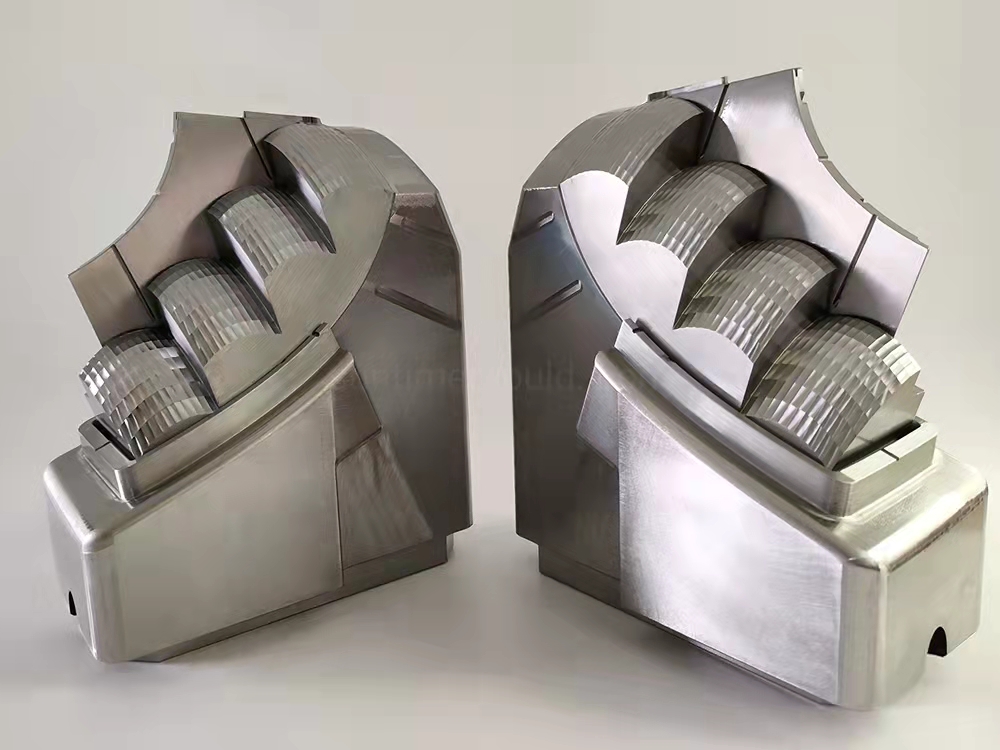

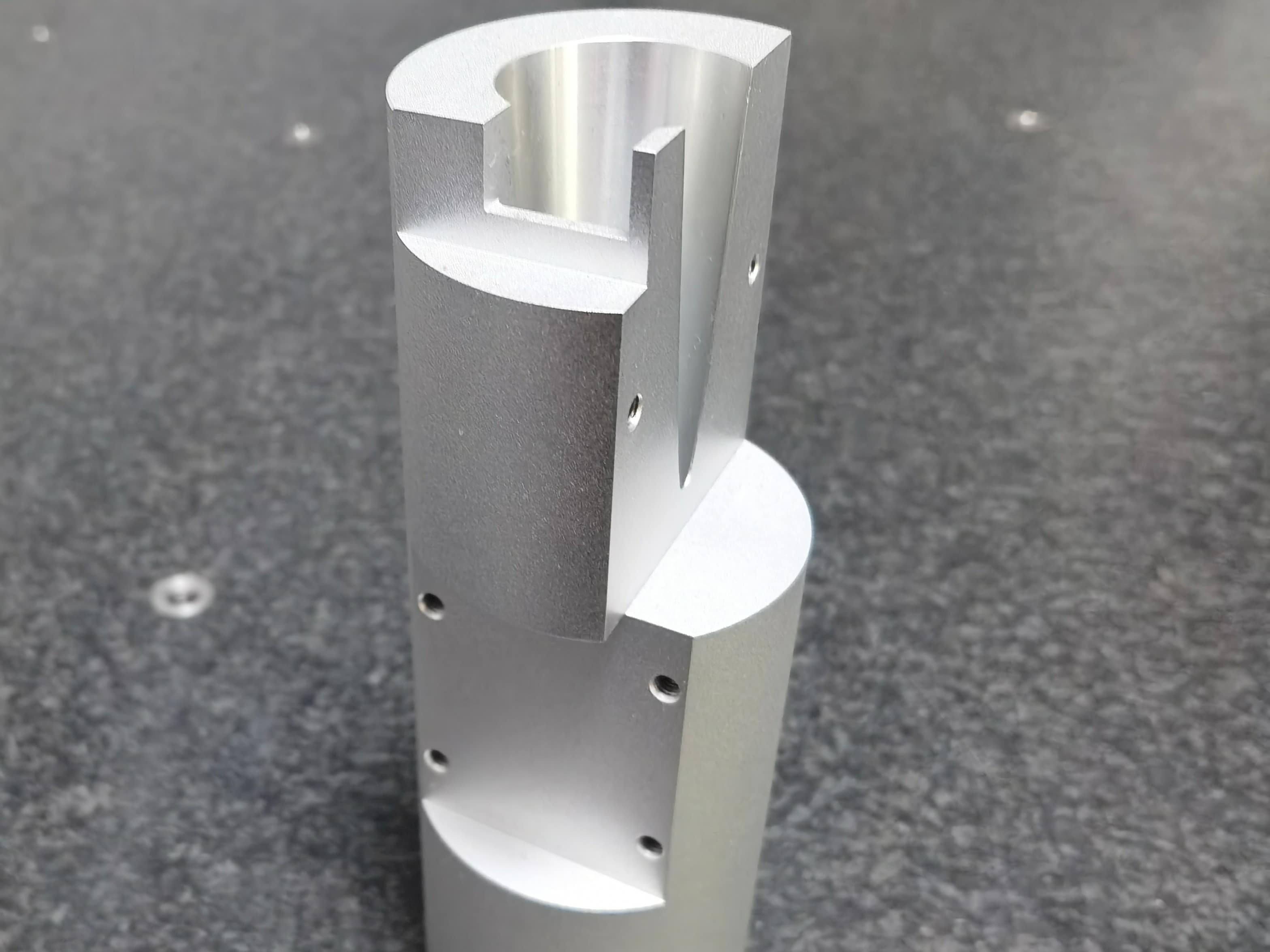

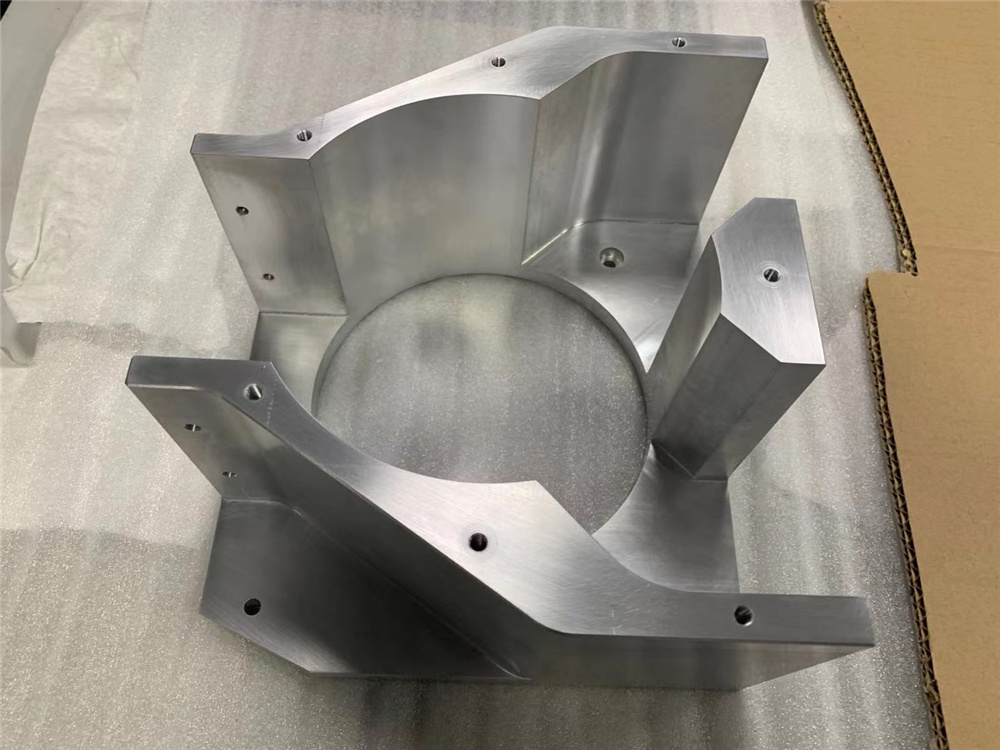

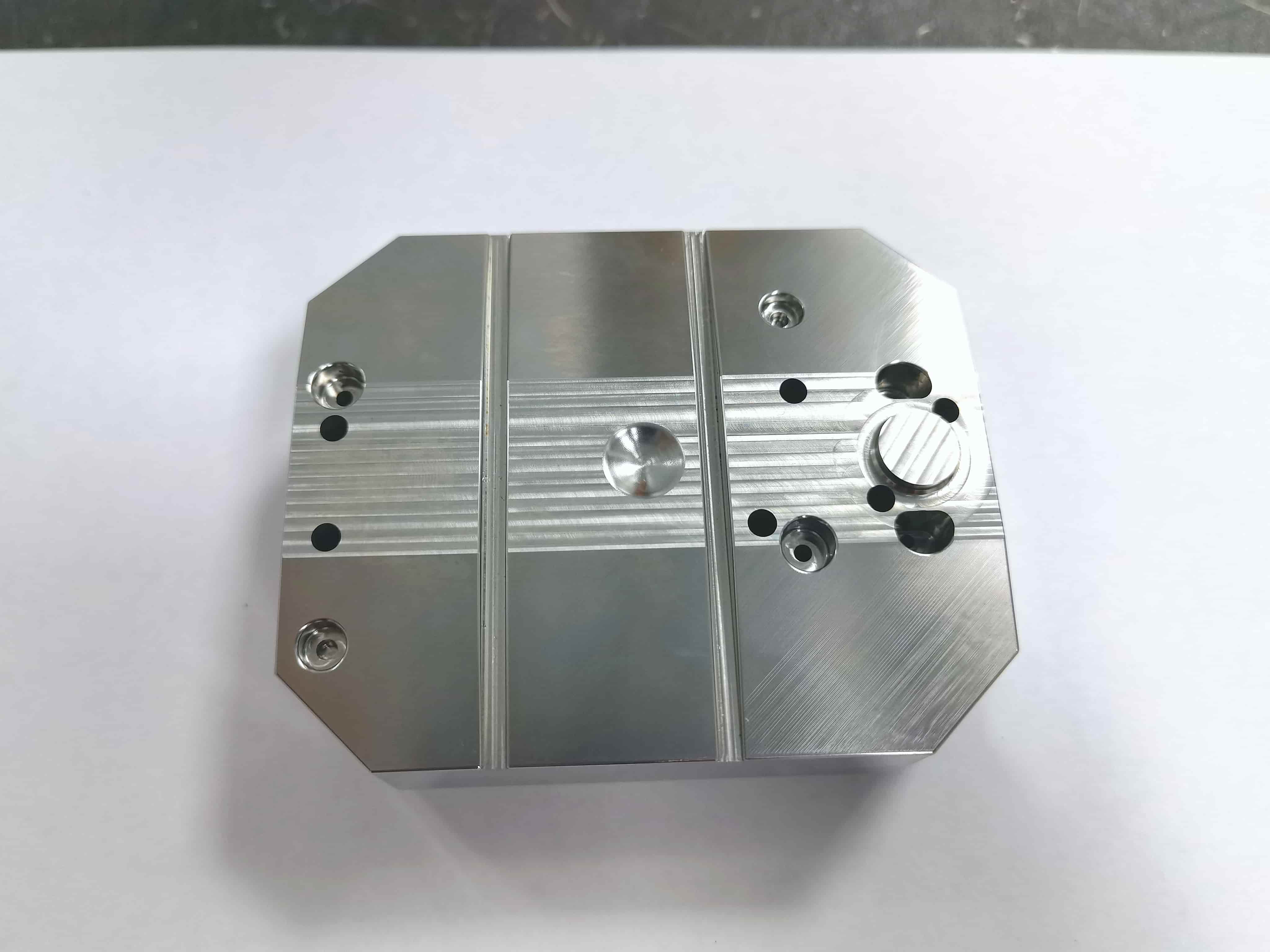

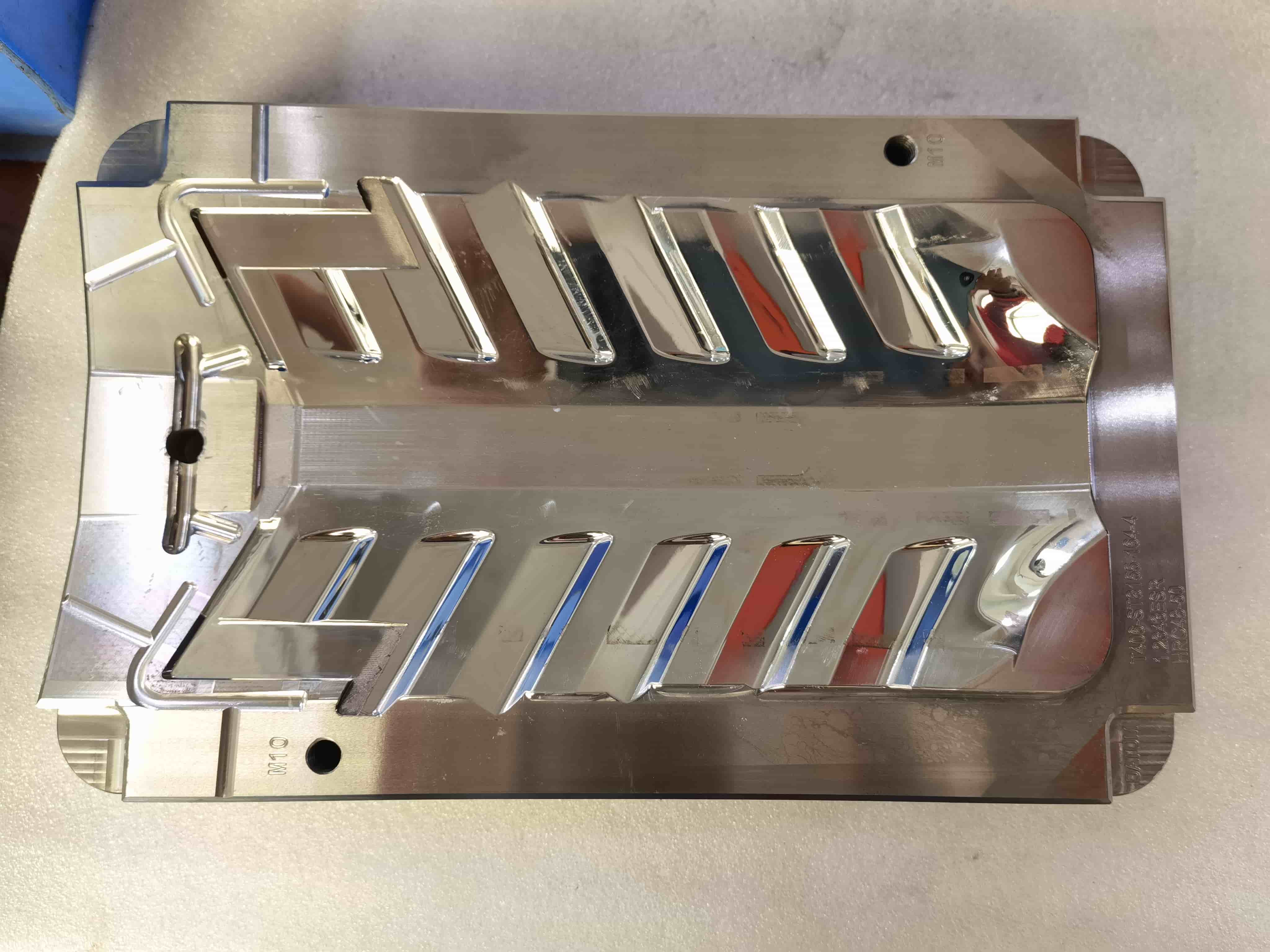

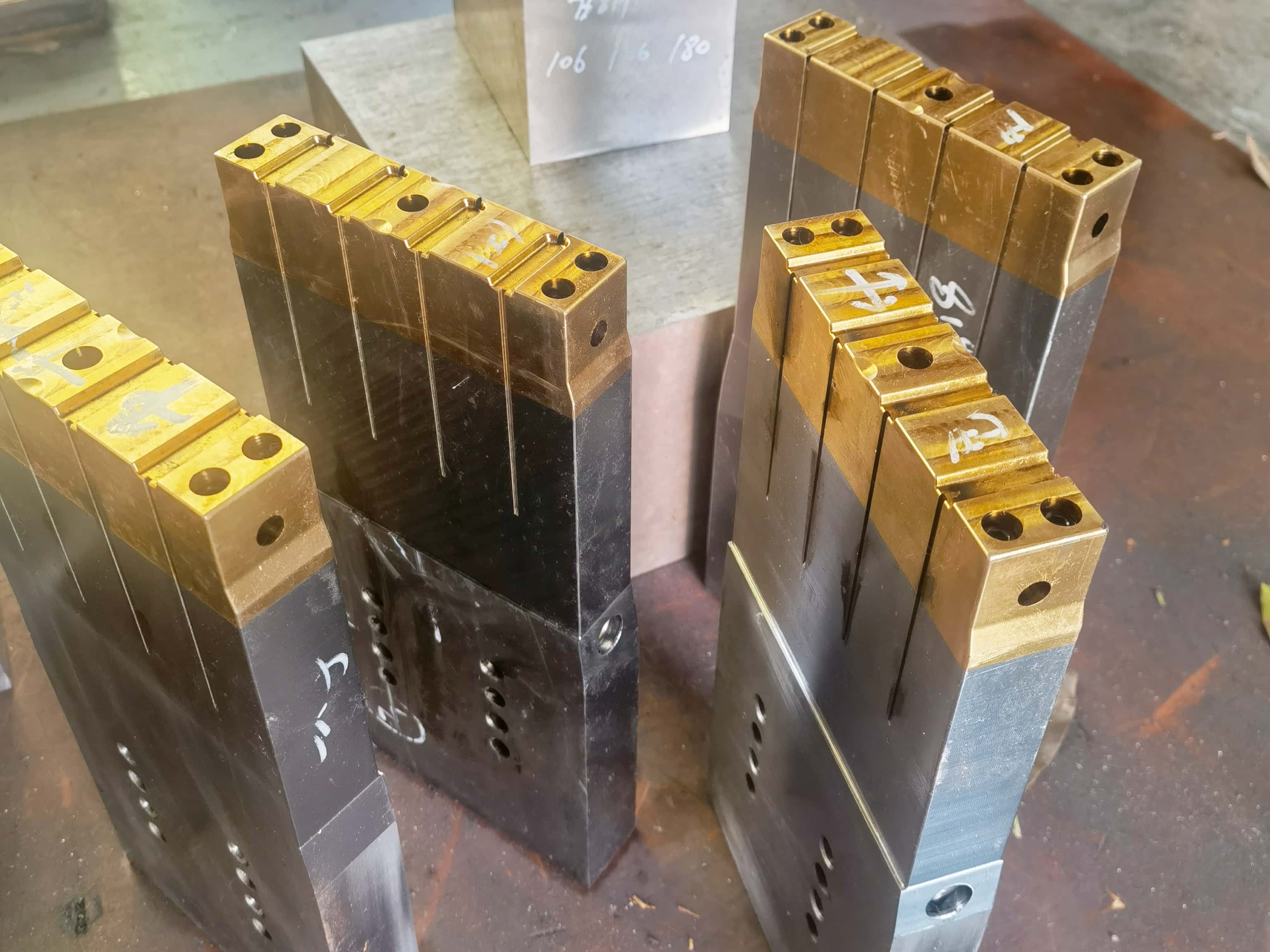

Steel components reference

Doing quality control for CNC machining is an essential step in the production process. With the right procedure, an engineer can ensure that all parts reach the highest precision and maintain a high level of accuracy.

• Start with choosing the correct cutting tool and material.

• Inspect the program before you start cutting. Ensure that all settings are optimized to meet your needs and that there are no mistakes.

• Pay close attention to safety guidelines such as wearing protective gear, keeping hands away from moving parts, and other instructions listed within your manual or from your employer's regulations.

• Check all components before beginning production with a sample inspection test run to identify any minor issues beforehand and make adjustments where needed before starting a full-scale run of parts.

• Test each individual component including dimensions, tolerances, surfaces, and structures, etc during production(IPQC) and after production(FQC).

• Comply with the standard of ISO 9001, make sure smooth production and quality control process.

• Before shipping, inspect and record based on our OQC documents and file them as future reference.

• Packing parts properly and using plywood boxes for safe transportation.

• Tools for inspection: CMM (Hexagon) and Projector, Hardness testing machining, Height gauge, Vernier caliper, All QC documents.....

If you have drawings, please send to us with your requests such as quantity, surface finish and material type.

For drawings format, please send us 2D of DWG / PDF / JPG / dxf, etc. or 3D of IGS / STEP / X-T / CAD, etc.

Or, if you don't have drawings, please send us your samples. We will scan it and get the data.

FAQ for CNC Machining

The CNC machining price is based on parts complexity, quantity and how soon you want to get the parts.

Complexity will determine the machines types and machining crafts.

And more quantity will cause lower part cost on average.

The sooner you want to get the parts, the cost may be a little higher than normal production.

* Repeatability

* Tight tolerance

* Quick-turn production ability

* Cost-saving for low volume production

* Customized surface finish

* Flexibility for material selection

* CNC milling

* CNC turning

* CNC wire - EDM

* CNC grinding

AL6061, Al6063, AL6082, AL7075, AL5052, A380.

Polishing , Anodizing , Oxidation, Bead blasting, Powder coating, plating and Surface brushed etc

CNC machining products can be used in industrials like Automotive, Medical, Aerospace, Consumer products, Industrial, Energy, Furniture, Electronic industries etc,.

SPM can provide MOQ from 1pcs.

If you have drawings, please send to us with your requests such as quantity, surface finish and material type.

For drawings format, please send us 2D of DWG / PDF / JPG / dxf, etc. or 3D of IGS / STEP / X-T / CAD, etc.

Or, if you don't have drawings, please send us your samples. We will scan it and get the data.