Factory source Telecommunications Turning And Milling Parts - Big size plastic injection mould for automotive car parts – Suntime Detail:

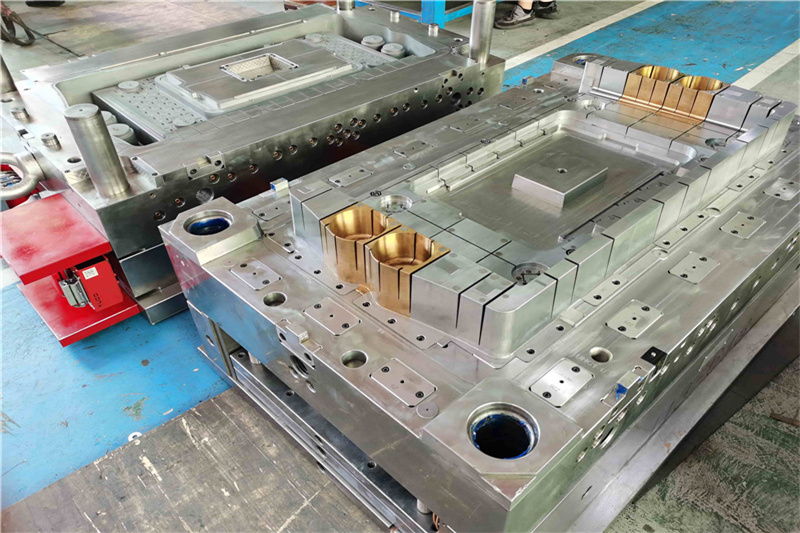

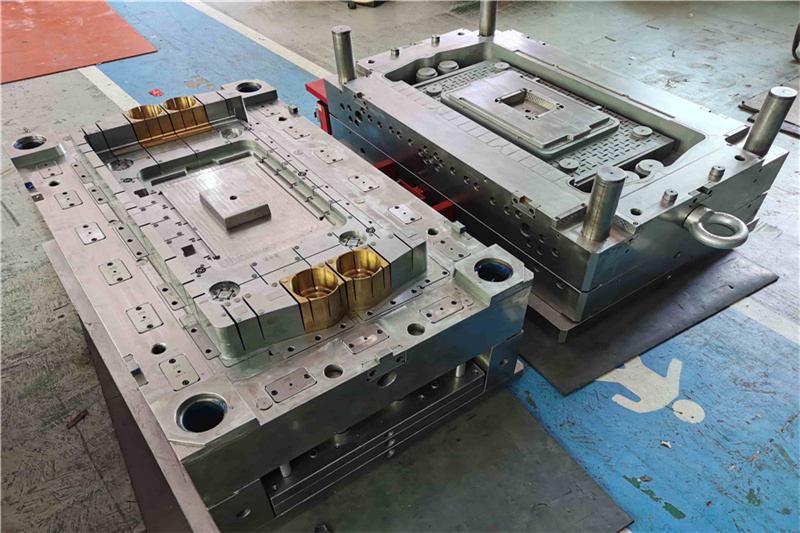

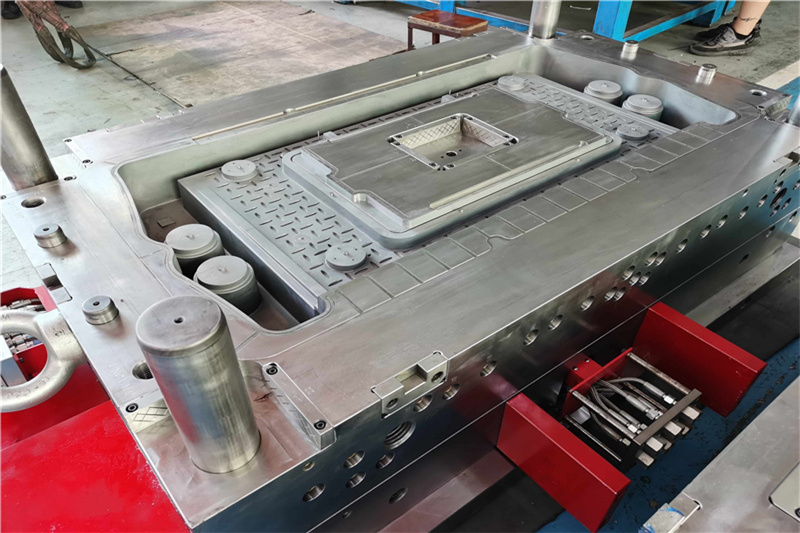

This product is one of the components for gold cart. Part is big and have deep ribs, need to do well to control the warpage. We used Becu inserts for cooling in deep rib area. Besides on controlling warpage, the balance filling is also very important. Suntime has experience designers and engineers, their rich working experience for these kind of big parts guaranteed the high quality and timely delivery.

| Appliance and Type | Component for golf cart | |||||

| Part name | SEAT KIT BASE | |||||

| Resin | PP-GF30 | |||||

| No. of cavity | 1 Cavity | |||||

| Mould Base | LKM S50C | |||||

| Steel of cavity&Core | 738 H HRC33-36/738 H HRC33-36 | |||||

| Tool weight | 5943KG | |||||

| Tool size | 1610 X 1070 X 867 | |||||

| Press Ton | 1200T | |||||

| Mold life | 300000 | |||||

| Injection system | 6pcs valve hot tips | |||||

| Cooling system | temperature 50 ℃ | |||||

| Ejection System | stripper plate and ejection pins | |||||

| Special points | Big part, deep rib and high request of cooling | |||||

| Difficulties | Need to control well for deformation, used Becu inserts for cooling and control well for filling. | |||||

| Lead time | 5.5 weeks | |||||

| Package | Anti-rust Paper and film, little anti-rust oil and plywood box | |||||

| Packing items | Certification of steel, final 2D & 3D tool design, hot runner document, spare parts and electrodes… | |||||

| Shrinkage | 1.005 | |||||

| Surface finish | MT1055-2/B-2 | |||||

| Trade terms | FOB Shenzhen | |||||

| Export to | USA | |||||

Suntime has very effective mold designers. For DFM, it can be finished within 1~2 days, mold flow / 2D layout within 2~4 days, and 3D within 3~5 days depending on mold complexity.

DFM Analysis

Mold flow

2D layout

3D mould design

Before molds shipping, we will double check the injection tools with our checking list to make sure every details are correct as customers’ requests. We use anti-rust paper to pack the mould after using very little anti-rust oil, so that customer can save more time in doing molds cleaning after receiving them (using mold clean agent or just molding some shots to clean it).

Suntime Precision Mould are much experienced in automotive big parts, The biggest one reach to 13 ton and 2.1m height for Toyota RAV4 side step. Our crane is 10 Ton which can make around 20 ton big tools. Our good price and quality will bring you more value.

1. How about the largest mold Suntime Precision Mould ever made? What about the smallest part?

13 ton with 2.1 meters long for TOYOTA parts. The smallest part we have made is 8 cavity mould for Apple male connecter.

2. What surface can you make?

“For mold: SPI,VDI3400, Mold-Tech, YS, Nitriding, Titanizing, Teflon coating… For parts: SPI,VDI3400, Mold-Tech, bead-basting and anodizing, Painting, Plating…”

3. If something you can’t do, will you tell the truth?

Absolutely, we will tell the truth. We only do what we can do, and do well what we do.

4. Do you material have certifications?

Yes, all our material for production, such as heat treatment, steel, plastics, silicon, aluminum, stainless steel and son on, have material certification / Rohs. If necessary, we can arrange to make SGS inspection.

5. How many samples are free for mold trials?

For small parts, we provide 15pcs as free samples after trials including free express shipping. When parts are very big, free samples will be around 1~3 pcs with free express shipping.

Product detail pictures:

Related Product Guide:

Our company insists all along the quality policy of "product quality is base of enterprise survival; customer satisfaction is the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff" and the consistent purpose of "reputation first, customer first" for Factory source Telecommunications Turning And Milling Parts - Big size plastic injection mould for automotive car parts – Suntime, The product will supply to all over the world, such as: Chicago, Zambia, Czech Republic, Our company has always insisted on the business principle of "Quality, Honest, and Customer First" by which we have won the trust of clients both from at home and abroad. If you are interested in our solutions, you should do not hesitate to contact us for further information.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.

-

OEM Manufacturer Mould Suppliers - Value added...

-

High Quality for Prototype Mould Making - Moul...

-

China Factory for Automotive Interiors Custom-I...

-

High Quality Cnc Machining For Iot Industry - ...

-

Cheapest Price Automotive Interiors Custom Plas...

-

Leading Manufacturer for Pharmaceuticals Plasti...