Factory wholesale Custom Injection Molder And Manufacturer For Mining Industry - Mold Making – Suntime Detail:

1.Part 2D/3D drawings. If no drawings, clear photos showing the structure and dimension, or, samples to our factory directly.

2.Cavity quantity. How many cavities will have big impact on tooling price and lead time.

3.Steel material. Different material has different mold life and advantages, it will affect the tooling price a lot. If you don’t know material, telling us the annual volume will be helpful.

4.Runner type, cold runner and hot runner have different cost and specialties.

5.Plastic material (resin). This is not a must, but knowing it will be very helpful to make an accurate price estimation.

Pre-sales support(quotation, material choose, DFM analysis, tooling configuration…)—> PO —> DFM —> 2D —> 3D—> Manufacturing—> trials—> modification/ correction—> T2, T3….—> Double check before delivery—> empty running before shipping—> final documents and certification preparation —> packing—>shipping on time—>after sales support

Basic information for mold manufacturing in Suntime

| Mold making capability:

* Aluminum die casting mold * Single plastic injection mold * Multi-cavity injection mold * Family moulds * Hot runner systems mold * MUD mold * Over mold * 2K mould * Thin Wall mold * Rapid prototyping mold |

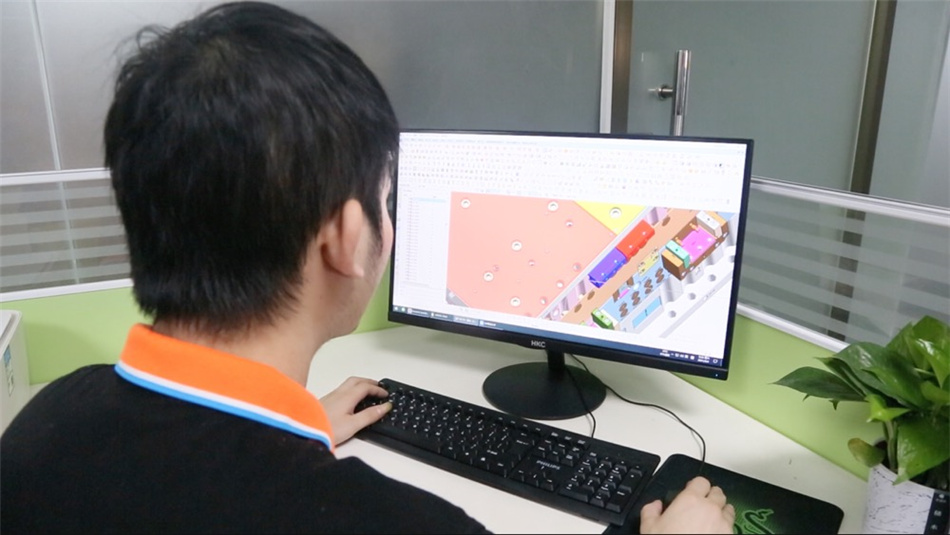

Software related:

Mold Flow: Mould Flow Analysis 3D Modeling: Pro/Engineer, Unigraphics, Solidworks 2D Drawing: Auto-CAD, E-drawing CNC Programming: Master-CAM, PowerMill All following international data format works OK for us: 2D drawing files: dwg,dxf,edrw ; 3D drawing files: step,Igs,X-T,prt,sldprt. |

| Materials:

Steel: GROEDITZ/ LKM/ ASSAB/ DAIDO/ FINKL… Mould Base: LKM,DME,HASCO,STEIHL…. Standard Components: DME, HASCO, LKM, Meusburger…. Hot Runner: Mold master, Mastertip, Masterflow, Husky, Hasco, DME, Yudo, Incoe, Syventive, Mold master… Polishing/Texture: SPI,VDI, Mold-Tech, YS…. Molding Resin: A380 (Aluminum alloy), PEEK, PPSU,ABS, PC, PC+ABS, PMMA, PP, HIPS, PE(HDPE,MDPE,LDPE). PA12, PA66, PA66+GF,TPE,TPR,TPU, PPSU, LCP, POM, PVDF, PET, PBT, etc,. |

Design and Engineering:

* Quotation 1~2 working days (free DFM is needed) * DFM: 1~3 working days * Mold flow: * 2D design: 2~4 working days * 3D design: 3~5 working days * Weekly report every Monday * Report to customers anytime

Communication: Email, telephone, video meeting, SNS and annal visiting

24/7 on call ! |

| Tooling Capabilities:

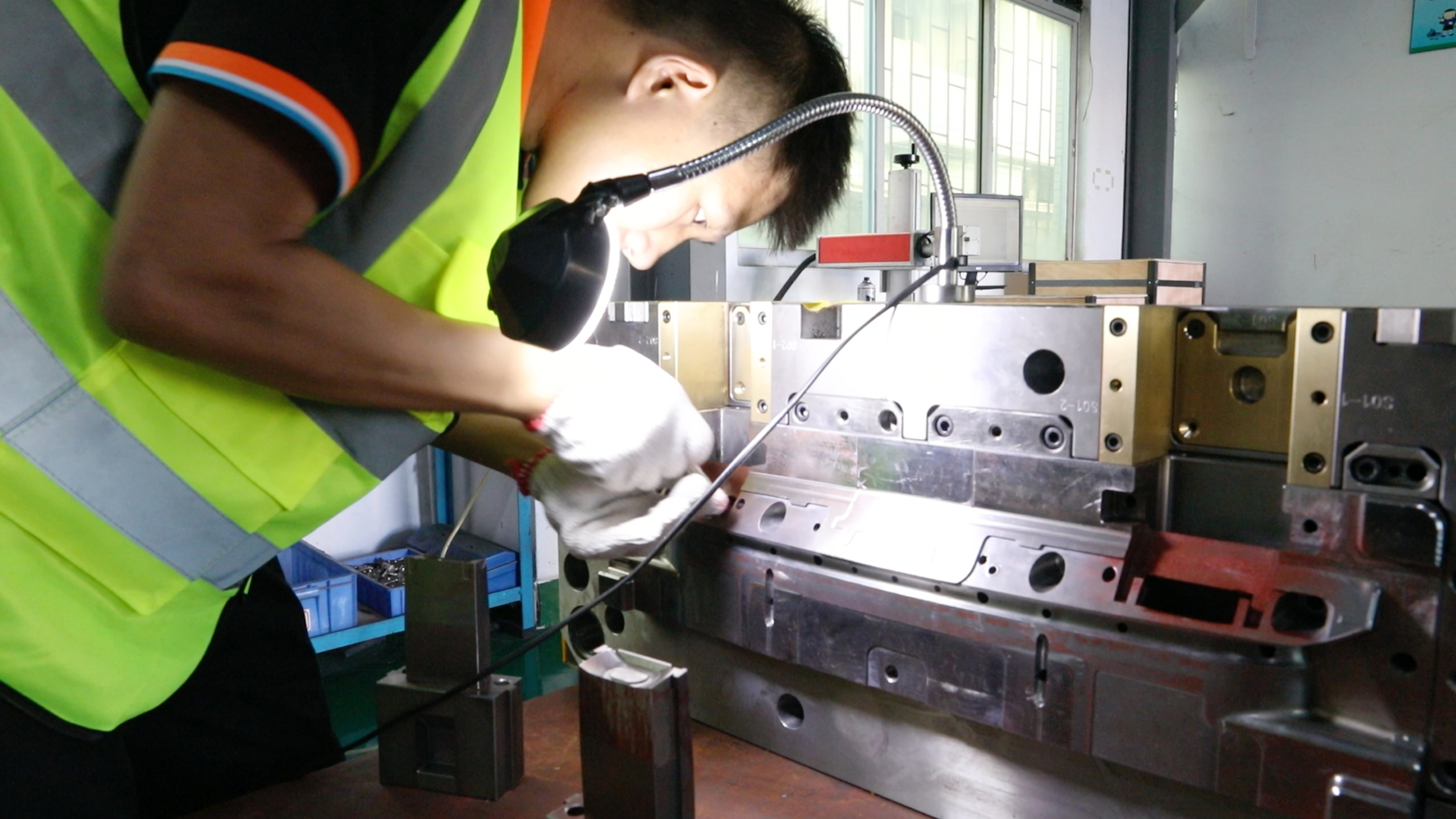

Fully equipped tooling facility ISO 9001:2015 certificated Experienced tooling staff CMM Inspection Injection machines for trials complete QC documents Effective working follow |

Production Lead Time:

Design 1~3 Weeks for all design and communication

Tooling manufacturing 3.5-8 Weeks up to 12 ton mold

Production Days to several weeks depending on quantity |

What is a good mold? It must have good quality to meet production requests stable & smoothly, and no need to spend too much time & cost for maintenance and repair. A good mold design is the start. Suntime has 6 designers in total with more than 5-10 years’ experience, they always pay special attentions on customers’ specification and details by thinking about the cost-saving solution based on stable and good quality. Their years’ experience for exporting molds give them great knowledge of global mold standards.

•With customers’ parts drawing (2D&3D) and specification, we hold meetings with designers, engineers and operation manager together to learn details and make memo of the projects.

•After that, our designers start DFM. With customers approval,they start the 2D layout & 3D mold drawing & Mold flow analysis.

•During all the process, weekly report will be provided every Monday to make sure customers have all things under control.

When Mold trial date comes, we will send trial report with mold photos, samples photos, short shot photos, part weight photo and issues we found and provide our solutions accordingly. After

•When Mold trial date comes, we will send trial report with mold photos, samples photos, short shot photos, part weight photo and issues we found and provide our solutions accordingly. After customers’ checking, we will send samples by express. Inspection report and moulding report will be sent for customers’ review.

•Mold corrections or modifications will be started at once after communication with customers. Normally, second trial will happen within 3~7 days.

•When samples get approved, we will double check & clean mold for delivery. Engineers will use check list to inspect every details, and take photos for Lift strap, Electrical connectors, Water fittings, Core and cavity, Shot counter etc, to customers for file. Protected oil will be used for shipping, but will not be much as Suntime uses anti-rust paper to protect it during transportation, so that customers have no need to spend too much time on cleaning the tools after they arrive

•Final 2D &3D mold drawings will be copied in a memory stick to packed together with steel certification, heat treatment certification, spare components and electrodes,etc,.

•For transportation including air shipping, sea shipping, train shipping and express shipping, we execute as customers’ requests and work tightly with forwarders.

•During all of these process, Engineers and Sales will be both of your windows for all supports. Their 24/7 working style gives you timely response on your concerns. Flexible working time will be helpful for any emergency.

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Factory wholesale Custom Injection Molder And Manufacturer For Mining Industry - Mold Making – Suntime, The product will supply to all over the world, such as: United Arab Emirates, Doha, Uganda, In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a specialist engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We have been your best choice.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.

-

High reputation Mining Industry Plastic Injecti...

-

Super Purchasing for Plastic Injection Mold Mak...

-

Reasonable price Agricultural Industry Plastic ...

-

High Quality for High Quality Precision Mould M...

-

Hot sale Factory Fishery Parts Plastic Molded P...

-

2021 wholesale price Good Price Cnc Machining F...