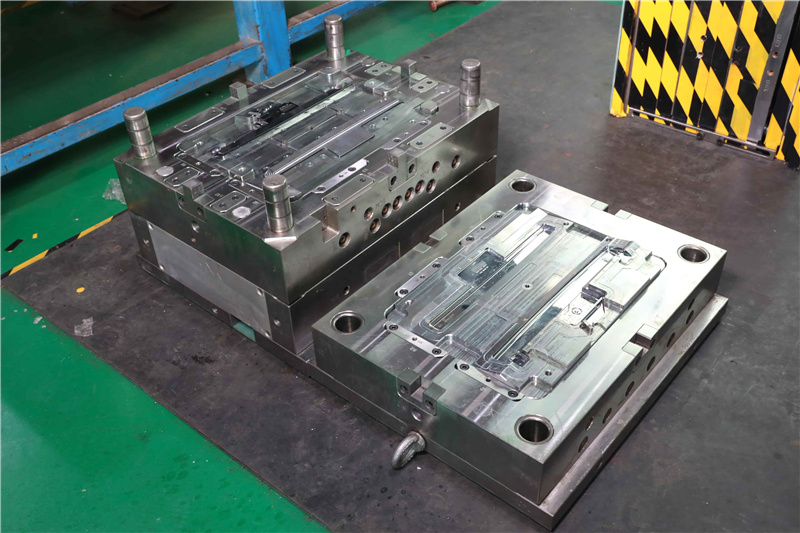

High Quality Battery Cover Thermoplastic Injection Moulding - Plastic tooling family mould automotive mould of car lighting lens – Suntime Detail:

These products are the very nice. Suntime Precision Mould spent 4.5 weeks for manufacturing. It is for car tail lighting with surface A1 polishing. The main difficulty is tooth profile and how to control the warpage. The tooling process includes CNC machining, wire-cutting, EDM, grinding, drilling and polishing, etc,. We provided service for the famous car brand such as Bentley, Mercedes-Benz, BMW, Audi, Volvo, Toyota, Honda and so on.

| Appliance and Type | Automotive lighting lens from plastic injection family mould | |||||

| Part name | Housing and Lens (Automotive lighting) | |||||

| Resin | PC/ ABS and PMMA | |||||

| No. of cavity | 1+1 cavity family mould | |||||

| Mould Base | LKM S50C | |||||

| Steel of cavity&Core | P20 | |||||

| Tool weight | 950kg | |||||

| Tool size | 600X450X450 | |||||

| Press Ton | 160T | |||||

| Mold life | 500000 shots | |||||

| Injection system | Cold runner mould Edge gate | |||||

| Cooling system | 110 ℃ | |||||

| Ejection System | Strpper plates, ejector pins | |||||

| Special points | Products are for automotive lighting lens and housing, surface is A1 polishing. | |||||

| Difficulties | tooth profile takes difficulties for machining and polishing. Need to control well for warpage. | |||||

| Lead time | 4.5 weeks | |||||

| Package | Stored in Suntime factory for production | |||||

| Packing items | / | |||||

| Shrinkage | 1.005 | |||||

| Surface finish | A-1 | |||||

| Trade terms | Exwork | |||||

| Export to | UK | |||||

Suntime precision mould has more than 40% business for automotive parts, from single cavity simple automotive interior part to automotive tail lighting parts. We are ISO 9001 certificated. We have good quality control no matter in mold making or in plastic injection molding.

Drawings

2D layout

3D mold design

DFM Analysis

Mold flow

1. Does Suntime Precision Mould has ISO9001?

Yes, Suntime Precision Mould is ISO9001:2015 certificated.

2. How long do you make moulds quotation? What information do you need to provide for a quotation?

Normally, we quote within 24 hours (not include holidays and weekends). But for urgent projects, we can make it within 4~8 hours. If there are too many parts, we will need more time, but won’t be longer than 48 hours. For files of quoting, We need 2D or 3D part drawings and specification such as cavity number, steel request, material ect,. Sometimes, samples are also ok to quote. If you don’t have drawings or available samples, please send us the photos with dimensions and showing structure.

3. What famous Automotive brands you have made products for ?

We have make tooling and parts for brands for Bentley, Mercedes, BMW, Audi, Volvo, Toyota, Honda and so on.

4. How can you show the manufacturing process to your customers?

Our engineers will communicate with customers directly and send weekly report every Monday with the time schedule and photos. If customers requires more information, we can provide photos, video or having video meeting with them.

5. What about your mold package for shipping?

“After double check the mold before delivery, we will prepare a Memory stick with Final 2D&3D drawings, necessary Electrodes, Certification of steel and hard treatment, some replacement spare parts and other things that customers required together with mold.

We will use little protection oil on the mold and use Anti-rust paper in order to save customer’s cleaning time. The box will be Customized Plywood box.”

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for High Quality Battery Cover Thermoplastic Injection Moulding - Plastic tooling family mould automotive mould of car lighting lens – Suntime, The product will supply to all over the world, such as: Malta, Birmingham, Lisbon, We have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export products to other countries. We expect to cooperate with you to develop a larger market.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.

-

High Quality Cnc Machining For Iot Industry - ...

-

Original Factory Furniture Machined Metal Parts...

-

Good quality Plastic Injection Mould For Agricu...

-

Leading Manufacturer for Pharmaceuticals Plasti...

-

Manufacturer of Mold Making China - High glass...

-

Factory Price For Automotive Injection Mold Too...