Hot Sale for Custom Injection Molder And Manufacturer For Building And Construction - Auto unscrewing plastic injection mould with PPSU material high temperature mold – Suntime Detail:

The high temperature auto unscrewing project has mold temperature of 160 degree and resin temperature of 380 degree. This 4 cavity mold has cycle time of 39 seconds, and very smooth unscrewing movement. Part is high tolerance with less than +/-0.02mm. Parts are used in deep sea water system devices.

| Appliance and Type | Water system products auto unscrewing 4 cavity mould, PPSU material, high temperature mold | |||||

| Part name | MINI PISTON | |||||

| Resin | PPSU | |||||

| No. of cavity | 1*4 | |||||

| Mould Base | LKM S50C | |||||

| Steel of cavity&Core | H-13 HRC48-50 /H-13 HRC48-50 | |||||

| Tool weight | 430KG | |||||

| Tool size | 493X454X440 | |||||

| Press Ton | 120T | |||||

| Mold life | 800000 | |||||

| Injection system | Cold runner mould | |||||

| Cooling system | 160 ℃ | |||||

| Ejection System | unscrewing by motor and gear wheel | |||||

| Special points | mold temperature 160 ℃,material temperature 380℃。 | |||||

| Difficulties | unscrewing very smooth, cycle time 39′S,tolerance +/-0.02mm. | |||||

| Lead time | 5 weeks | |||||

| Package | Anti-rust Paper and film, little anti-rust oil and plywood box | |||||

| Packing items | Certification of steel, final 2D & 3D tool design, hot runner document, spare parts and electrodes… | |||||

| Shrinkage | 1.007 | |||||

| Surface finish | B-2 | |||||

| Trade terms | FOB Shenzhen | |||||

| Export to | Australia | |||||

We have made many tools for this customer. Our designers work very effective, for DFM, it can be finished within 1~2 days, 2D layout within 2~4 days, and 3D within 3~5 days depending on mold complexity. When time is very urgent, we normally make 3D drawing directly after DFM, but of course, it must be based on customers’ approval.

Design feedback

3D mold design

3D mold design

3D mold design

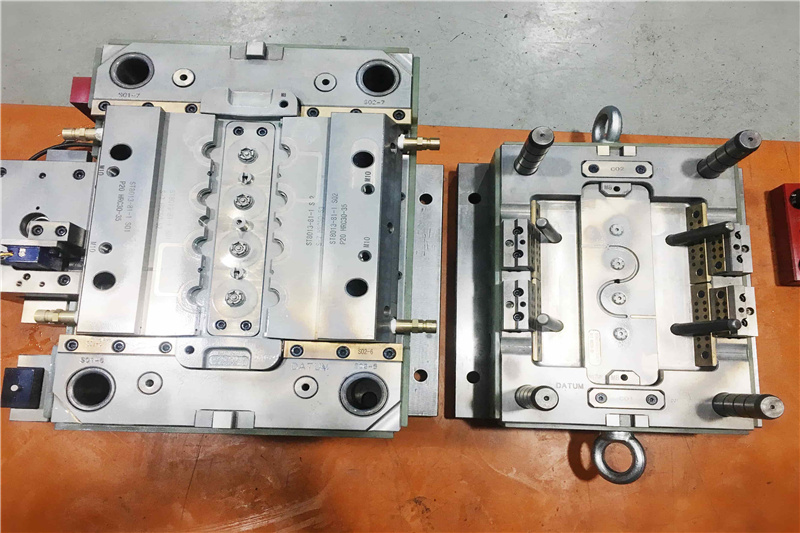

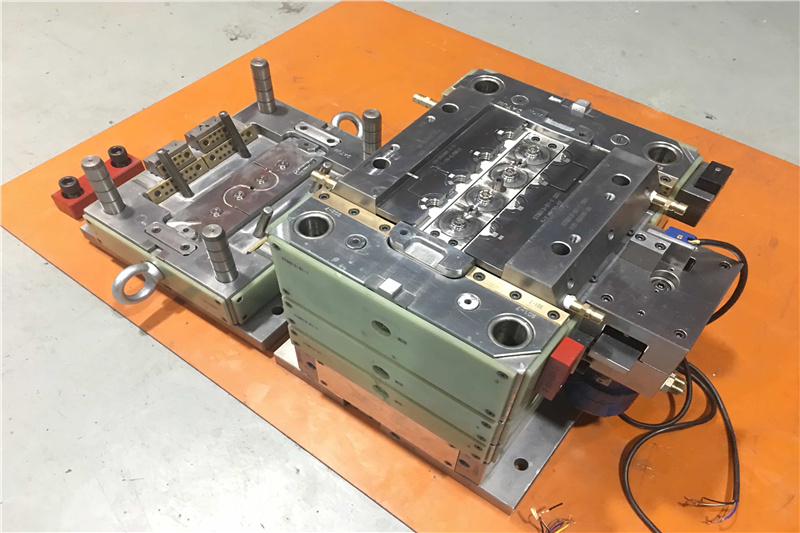

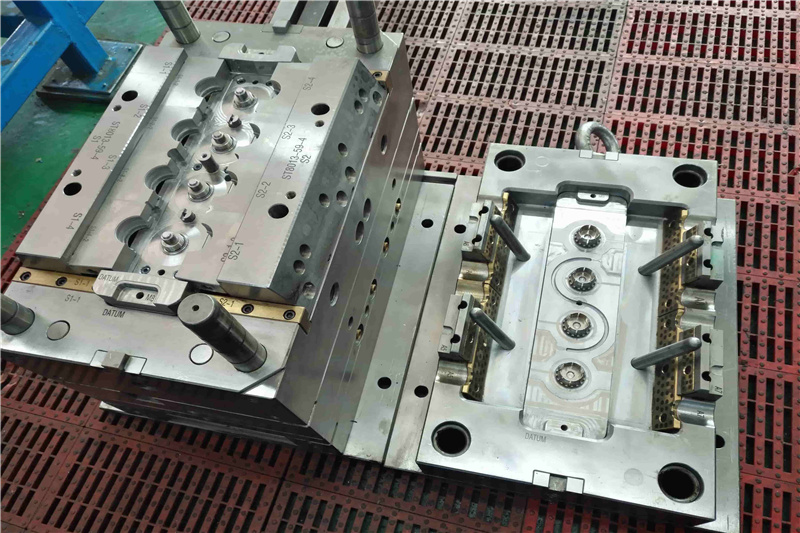

The injection mould tool is auto-unscrewing by motor and gear wheel. There are many insulation plates in mould four sides as the mold temperature is very high. This 4 cavity mold has moulding cycle time 39 seconds and the part tolerance is less than +/-0.02mm.

1. How is the mold temperature for this PPSU mold?

The mold temperature is 160~180 degree.

2.How about the tolerance for parts made in Suntime Precision Mould?

Mold: +_0.01mm, Plastic Part: +_0.02mm and Machining product: +_0.005mm.

3. What production material you usually use?

For plastic injection molding, resin includes PPSU, PEEK, ABS, PC, PC+ABS, PMMA, PP, HIPS, PE(HDPE,MDPE,LDPE). PA12, PA66, PA66+Glass fiber,TPE,TPR,TPU, PPSU, LCP, POM, PVDF, PET, PBT… And for die casting, the aluminum material is A380,A356,6061.

4. What is your design lead time?

“DFM: Normally Within 2 working day.

2D mold layout: Normally Within 3-4 working day.

3D mold drawing: Normally Within 4-5 working day.”

5. What regions is Suntime located?

Our factory is located in Chang An town of Dong Guan City in south of China, which is initial mold manufacturing place. 10 minutes to Shen Zhen. 30 minutes to Shen Zhen airport.

6. How’s your Communication skill?

“a). Rich experienced sales and engineers follow project and communicate in skilled English.

b). 24/7 style service. One to one project management.

c). Come to visit anytime and Suntime team visit customers yearly.

d). weekly report every Monday. (2 reports a week if needed).

e). Any emails reply within 24 hours, you can call us anytime, even in middle night. “

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Hot Sale for Custom Injection Molder And Manufacturer For Building And Construction - Auto unscrewing plastic injection mould with PPSU material high temperature mold – Suntime, The product will supply to all over the world, such as: Gambia, French, San Francisco, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end products, to do professional products.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

-

Wholesale Discount Prototype Parts - Plastic i...

-

Leading Manufacturer for Turning And Milling Pa...

-

Hot Sale for Automotive Interiors Injection Mol...

-

2021 wholesale price Die Casting Parts For Cons...

-

factory low price Tooling And Molding - CNC tu...

-

Factory Free sample Low-Volume Production For P...