Low Volume Plastic Injection Moulder for Telecommunication Products – Custom Injection molding for plastic products and Aluminum die casting parts – Suntime Detail:

No matter how small volume you want to produce, we can offer our best service with patience.

| Plastic Materials | Parts Surface | Applications | Molding type |

| PC/ABS | SPI A0,A1,A2,A3 (Mirror-like finish) | Automotive | Single cavity /Multi cavity molding |

| Polypropylene(pp) | SPI B0, B1, B2, B3 | Consumer electronics | Insert molding |

| Nylon GF | SPI C1, C2, C3 | Medical device | Over molding |

| Acrylic (PMMA) | SPI D1, D2, D3 | Internet of things | Unscrewing molding |

| Paraformaldehyde (POM) | CHARMILLS VDI-3400 | Telecommunication | High temperature molding |

| Polyethylene (PE) | MoldTech texture | Building & Constructions | Powder metallurgy molding |

| PPSU/ PEEK /LCP | YS texture | Household appliances | Clear parts molding |

| PVC/POM |

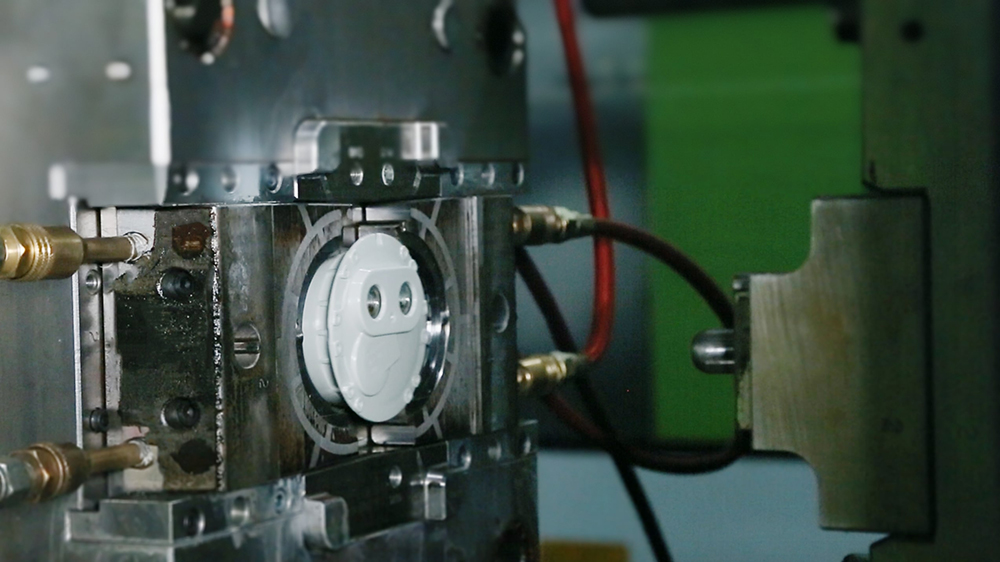

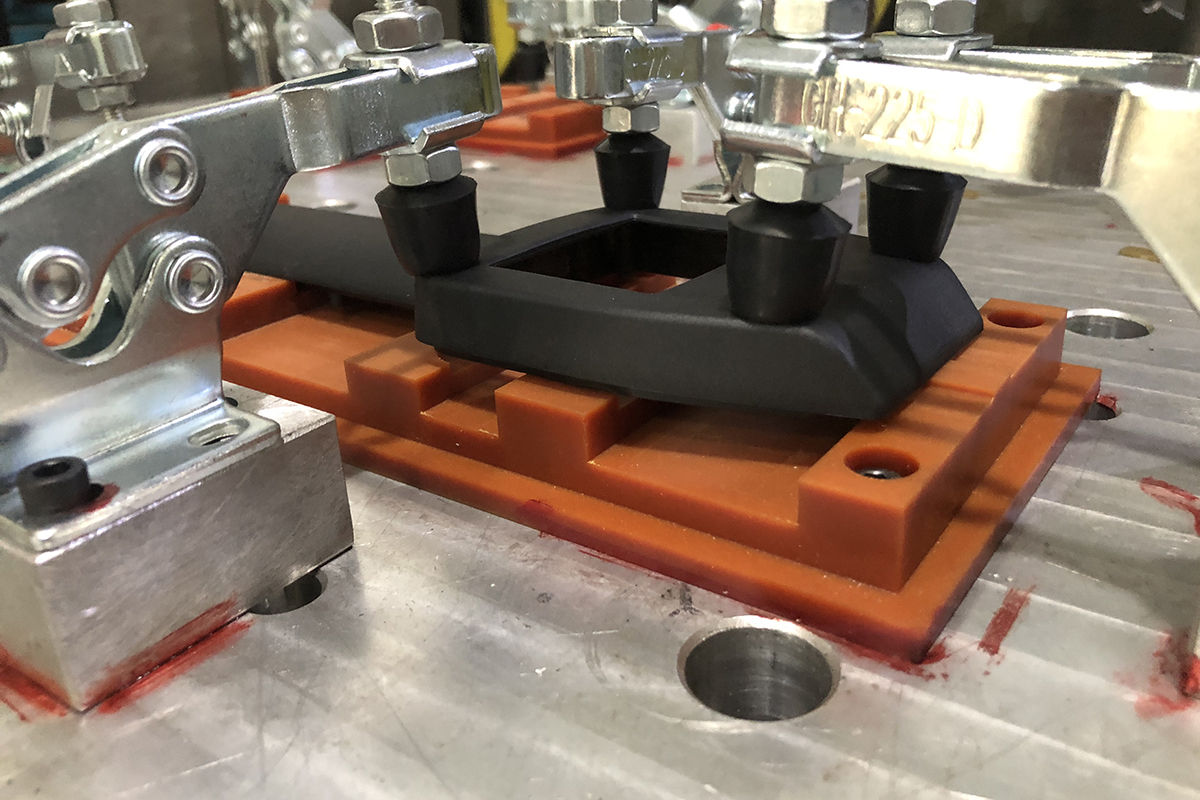

Fully equipped moulding facility and Experienced processing staff, 12 injection moulding machines range from 90 tonne to 400 tonne, ISO 9001:2015 accredited quality control process, Trials and molding production, MOQ from 1pcs

We encourage working with Non-Disclosure Agreements as this helps protect both parties. All your products are your investment of time and cost, we must respect it and it is the also good for our reputation.

Your tools are here in safe and cost-effective condition. As we are also a tool maker, we provide free service for tooling maintenance and repair. Even if your production volume is very low, we provide 3 years storage for free. If the production volume is high, when molding reach to mold life, we even can make a new mould for you for free too.

Quality is a basis for a company to survive. Our QC people have many years experience҅ combining with our inspection equipments such as Hexagon CMM, Projector, Vernier caliper and so on, we assure the dimension meeting customers’ requirements.

We have complete quality control working flow and related documents, for example, FAI report, CPK report if needed, IQC inspection report, IPQC report, FQC and OQC report and so on, all these documents help us to work more accurately and effectively, to assure parts quality is totally under control and traceable.

Training every week improves QC people’s strong sense of responsibility. In Suntime, there are clear rewards and punishments, which supervises our people to work more carefully and ensures the accuracy of data and quality judgments.

Our fast 24/7 communication by emails, phone calls and video meetings can assist any of your concerns and demand of consultancy

Please don’t hesitate to get in touch and speak to our experienced team if you want to know more about how we can help and support!

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and growth, we're going to build a prosperous future together with your esteemed firm for Low Volume Plastic Injection Moulder for Telecommunication Products – Custom Injection molding for plastic products and Aluminum die casting parts – Suntime, The product will supply to all over the world, such as: Canada , Turkey , Paraguay , With a wide range, good quality, reasonable prices and stylish designs, our solutions are extensively used in beauty and other industries. Our solutions are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.