When a product goes to stage of mould making, lead time is very important to make sure the products can launch to market timely. So, if the tooling lead time could be as short as possible, it will help a lot for end customers to bring their new products to market. Then, how to make the plastic injection molds with shorter lead time? Below is our opinion for your reference.

1. Suppliers needs to ask for customers’ time request for samples and moulds firstly so that they can estimate a rough time line for this project. (If they can’t do it, must be honestly to customers.)

2. Shorten the design time. When a part goes to tooling stage, there are normally many places needing to change to make it suitable for tooling, such as changing the draft angle, wall thickness and undercuts and so on. In this case, communication between customers’ engineers and mould suppliers much be very effective. Suntime make DFMs to customers in advance to show the areas where we think needing to change and send to customers very quickly within 1~3 days depending on parts quantity and complexity. Sales and engineers always give reminding timely and track tightly for customers’ feedback to avoid potential time waste. After DFM is ok, we will start to make 2D design , even if the deposit payment hasn’t arrive to us. In order to save time, we always make design in advance. Normally, 2D mould design needs 1~3 working days and 3D mould design needs 2~4 working days. Our designers work very effective and it assure our short design time.

3. During the design stage, easily & fully understanding of each other and timely communication is also important, it can save time for unnecessary emails or phone calls. Suntime mould team can speak and write English very well, engineers can reply English emails directly. And when there is a need to have a conference call, our team can do that anytime.

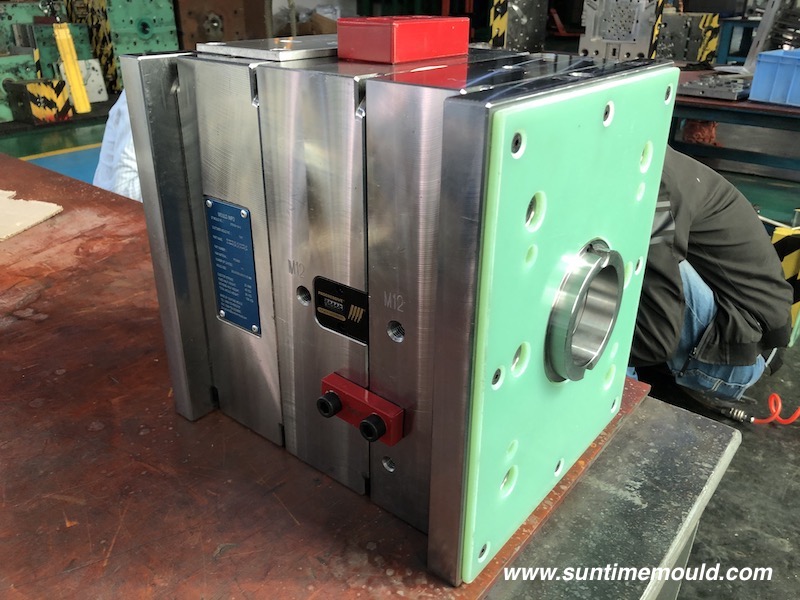

4. Then, it comes to mould manufacturing stage. Theoretically, manufacturing time can’t be cut short as we all know that good quality needs enough time. However, there is always urgent situation sometimes. When customers need shorter time, Suntime mould team can make T1 mould trial 1~2 days in advance by arranging over night working for free. But, our suggestion is not to push too much for manufacturing.

5. Now, it is the most important thing to short the total lead time— mould trials’ number of times. Mould making time is fixed, but mould trials are not fixed as corrections and modifications happen very often. Mould trials’ number of times is a big potential element of time waste. After T1, suppliers firstly need to check the problems and if the mould structure and mould components need to improve; inspect the moulding parameter to see if there is a better way to do the injection moulding. And if mould structure can’t help, engineers need to find out if there are still issues in the part’s structure and how to do the change based on not to change the assemble structure. After having the final conclusion, engineers need to make a mould trial report with photos to show the issues and our solutions for customer’s approval. At the same time, mold trail video, moulding parameter and samples inspection report need to be provided to customers for discussion. After having customers’ approval of correction & modification, we need to arrange the working at once and do the best to correct all issues in next trial. Normally, for small issues, T2 can happen 1 week later, and for complex problems, maybe need 2 weeks. Controlling the total number of trails within 3 times is a very good way to save time & cost.

Suntime mould have many years’ experience working with global customers, their satisfaction is our big confidence to say that we can work with you very well too.

Post time: Nov-09-2021