Quality is life for a company to survive. In Suntime, high quality products and service are the most important factors to get customers trust and support these years.

Our employees have more than 10 years experience for mold making and injection molding production. Combining with inspection equipments such as Hexagon CMM, Projector, Vernier caliper, hardness machine and so on, we assure the dimension meeting customers’ requirements.

We are ISO 9001 certificated, having complete QC working flow and related documents such as FAI report, CPK report, Electrode / sample / mould inspection report, mold delivery check list, Mold trial report, moulding parameter report, IQC, IPQC report and OQC report… all these documents assure the molds and parts quality under control.

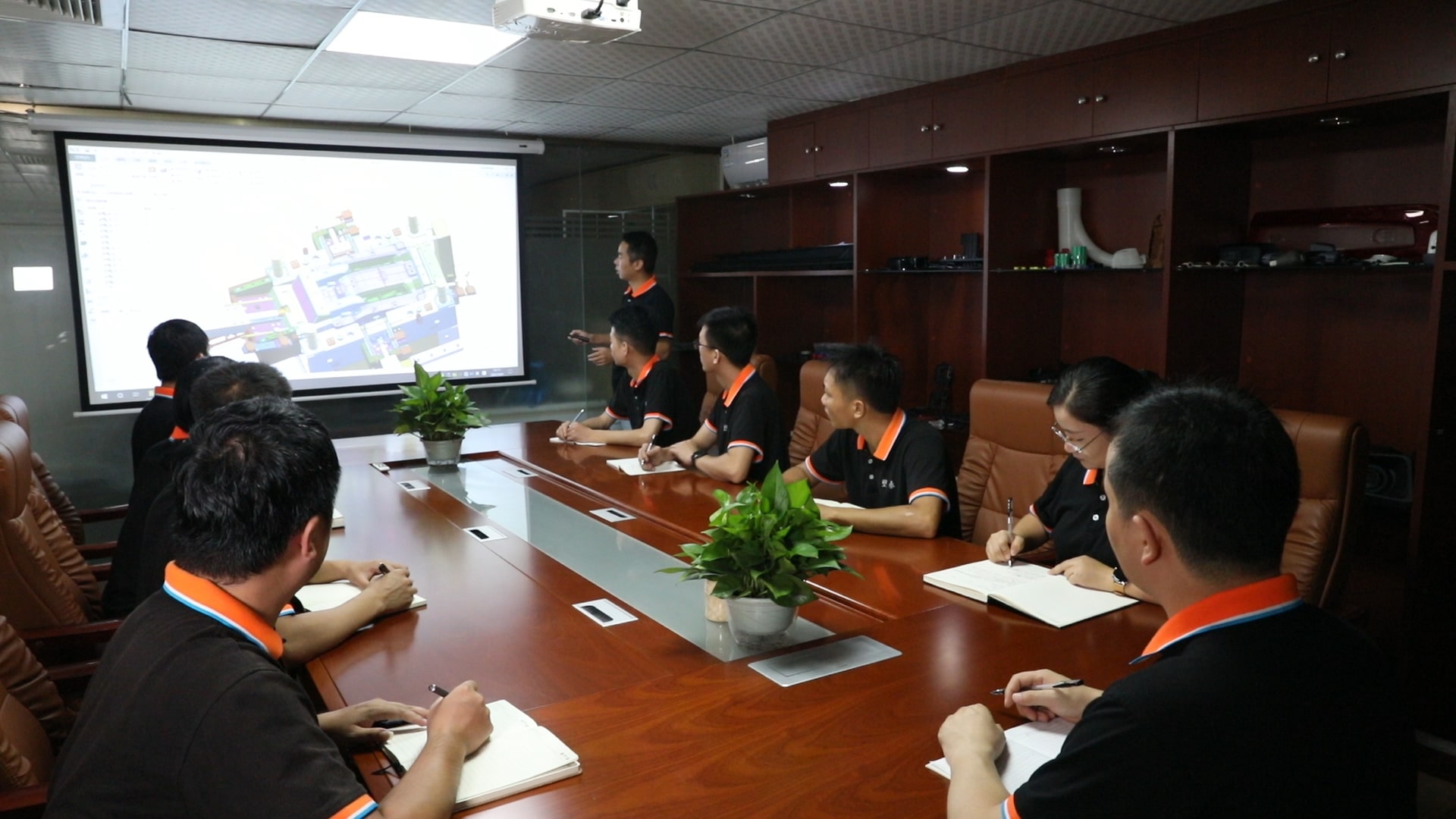

Every week, Quality and engineers have training, which improves their sense of mission and responsibility.There are clear rewards and punishments for QC department, so that workers is much more careful to guarantee the accuracy of data and correct judgments for quality requests.

Quality Assurance

* Designers, engineers and production manager hold kick off meeting for fully understanding of any new projects’ in details.

* Engineers contact customers one to one so that technical communication can be correct and fast.

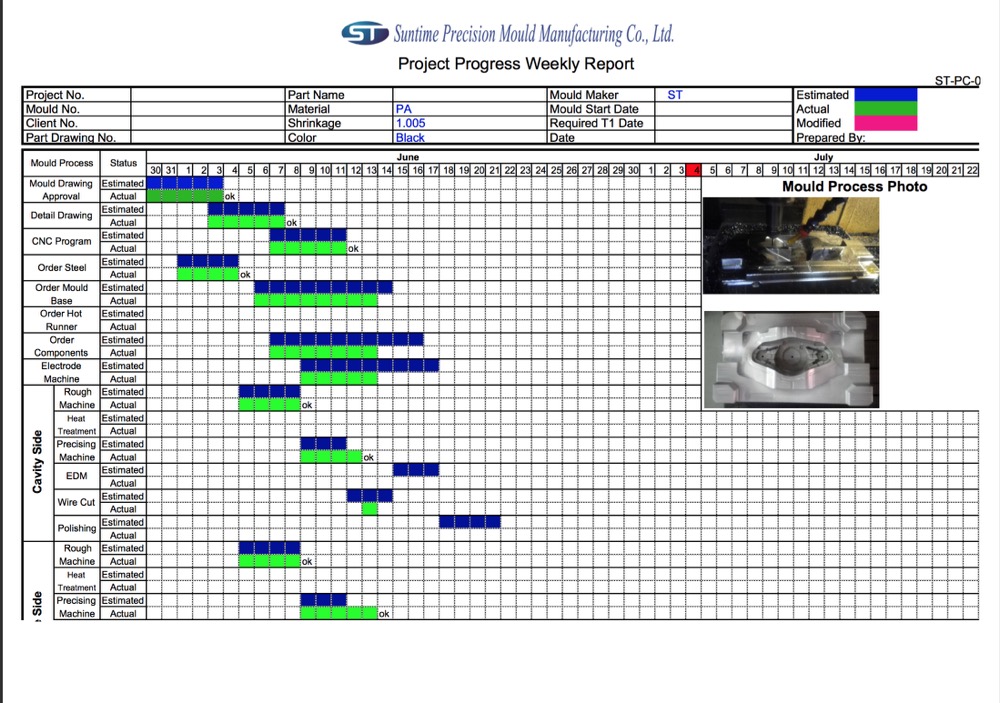

* Weekly report every Monday to let customers trace the projects easily. Suntime also can do anything that customers asked us to do for tracing the manufacturing.

* For mold trials, we provide trial report, mould running video, samples photos, shot short photo, injection moulding parameter and FAI report. Samples will be sent after customers' approval.

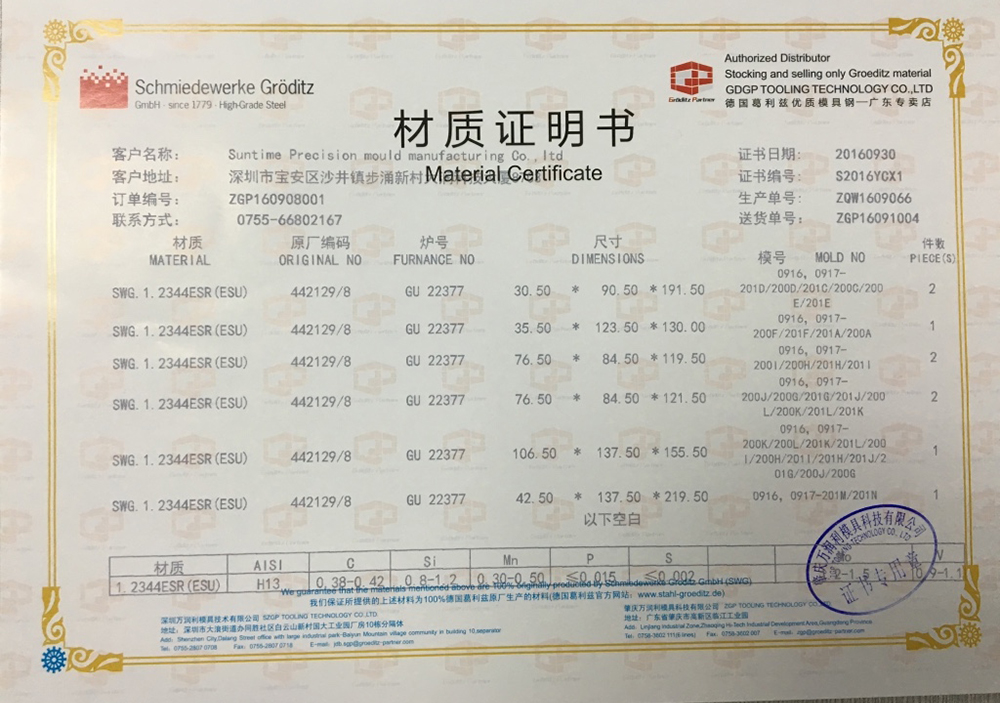

* Certification for steel, copper and plastics to make sure all materials are real and correct.

* Use famous high quality brand for Hot runner, Hydraulic cylinder and other components.

* Use Hexagon CMM, projector, vernier caliper, hardness tester and so on to do components and samples inspections.

* Check list to double check all the components and details before mold delivery.

* full documents like IQC, IPQC, FQC and OQC etc for moulding parts quality control

* Vacuum packing for moulds. Using plywood box and fix tightly to make sure safe transportation.

* Molded parts packing with high protected material such as bubble bag, foam box, film, plastic foam, paper layer, 7-ply carton box, fixing strap and plastic pallets to assure customers to have good parts after transportation.

* Suntime team visits customers every year for technical support & after service face to face. Any issues will be responded within 24 hours, we never find excuses for our mistakes if happened, we always take our responsibility for what we should take.

* For molding orders, we repair customers’ moulds and do regular maintenance for free in house.

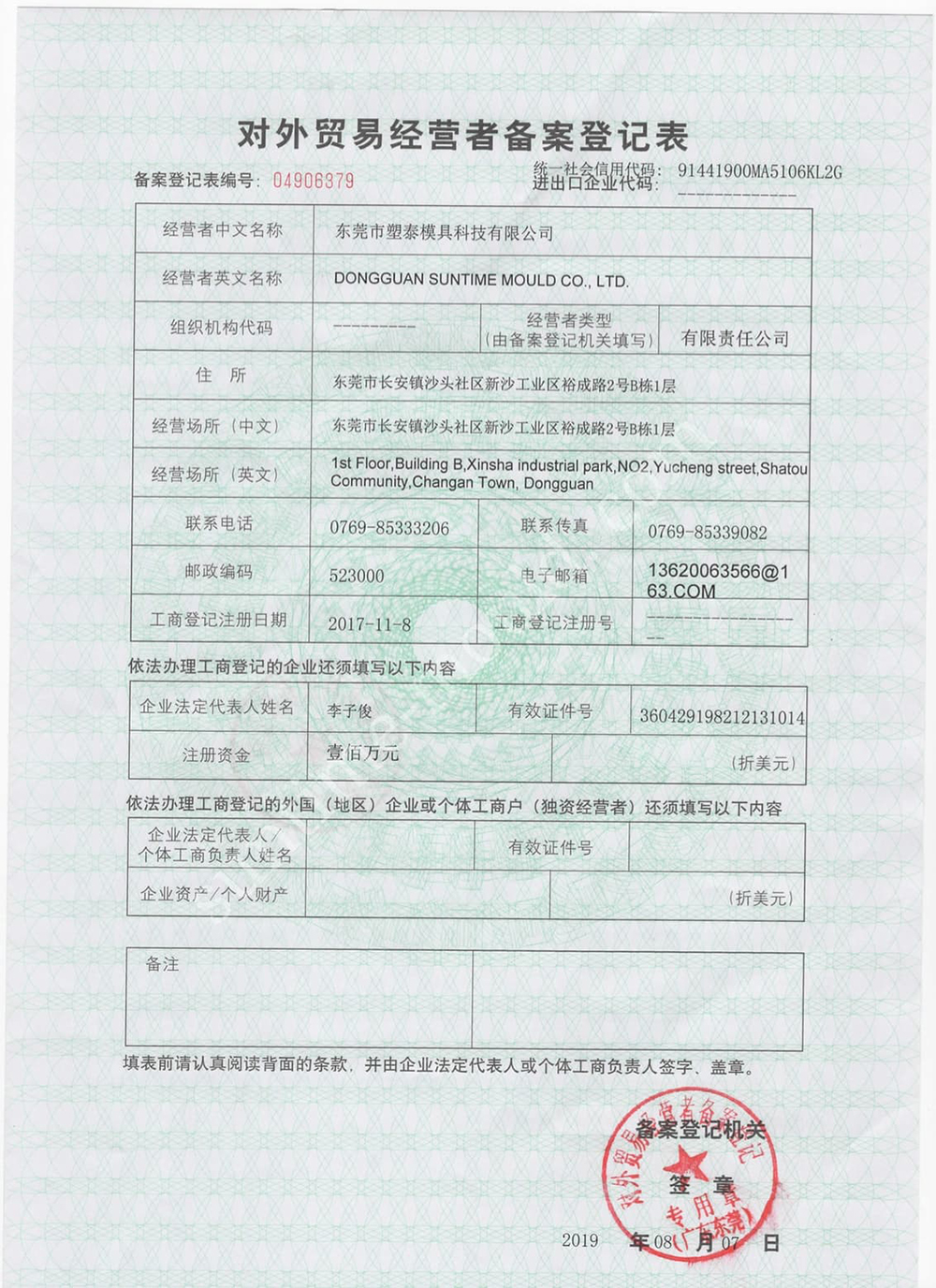

Certificates