Quality Inspection for Pharmaceuticals Plastic Injection Moulder - Auto unscrewing mould making & High temperature mold PPSU material – Suntime Detail:

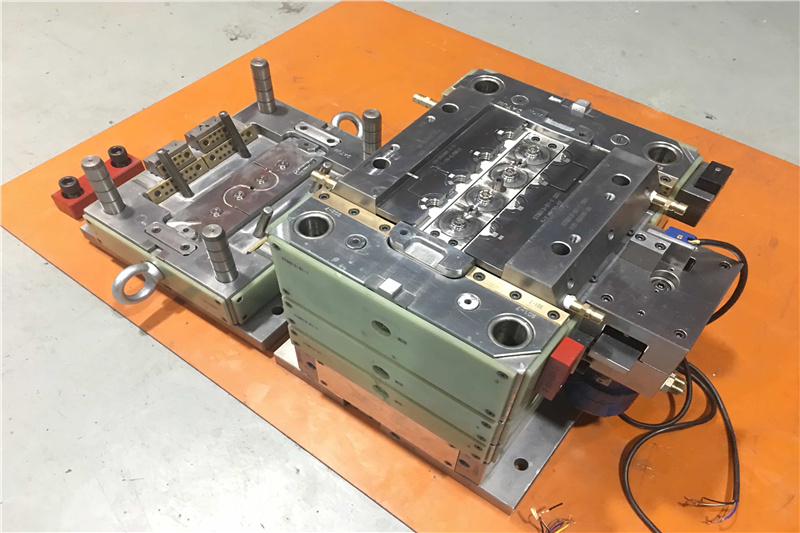

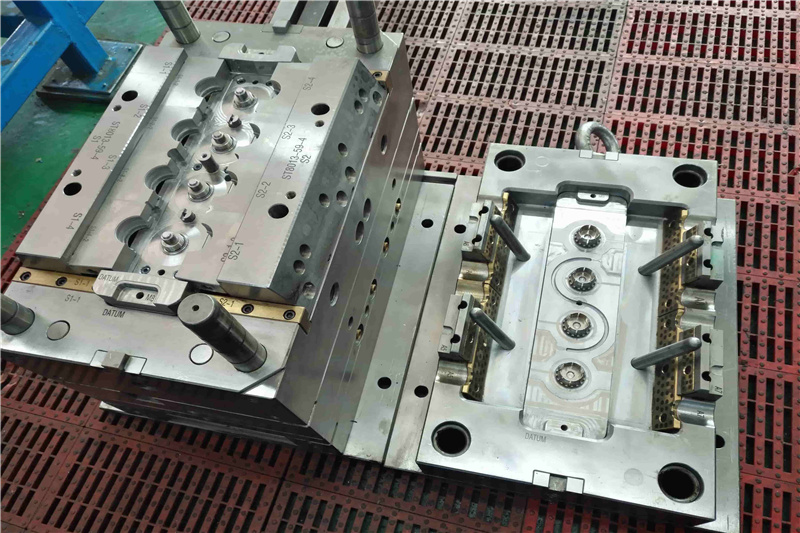

The high temperature auto unscrewing project has mold temperature of 160 degree and resin temperature of 380 degree. This 4 cavity mold has cycle time of 39 seconds, and very smooth unscrewing movement. Part is high tolerance with less than +/-0.02mm. Parts are used in deep sea water system devices.

| Appliance and Type | Water system products auto unscrewing 4 cavity mould, PPSU material, high temperature mold | |||||

| Part name | MINI PISTON | |||||

| Resin | PPSU | |||||

| No. of cavity | 1*4 | |||||

| Mould Base | LKM S50C | |||||

| Steel of cavity&Core | H-13 HRC48-50 /H-13 HRC48-50 | |||||

| Tool weight | 430KG | |||||

| Tool size | 493X454X440 | |||||

| Press Ton | 120T | |||||

| Mold life | 800000 | |||||

| Injection system | Cold runner mould | |||||

| Cooling system | 160 ℃ | |||||

| Ejection System | unscrewing by motor and gear wheel | |||||

| Special points | mold temperature 160 ℃,material temperature 380℃。 | |||||

| Difficulties | unscrewing very smooth, cycle time 39′S,tolerance +/-0.02mm. | |||||

| Lead time | 5 weeks | |||||

| Package | Anti-rust Paper and film, little anti-rust oil and plywood box | |||||

| Packing items | Certification of steel, final 2D & 3D tool design, hot runner document, spare parts and electrodes… | |||||

| Shrinkage | 1.007 | |||||

| Surface finish | B-2 | |||||

| Trade terms | FOB Shenzhen | |||||

| Export to | Australia | |||||

We have made many tools for this customer. Our designers work very effective, for DFM, it can be finished within 1~2 days, 2D layout within 2~4 days, and 3D within 3~5 days depending on mold complexity. When time is very urgent, we normally make 3D drawing directly after DFM, but of course, it must be based on customers’ approval.

Design feedback

3D mold design

3D mold design

3D mold design

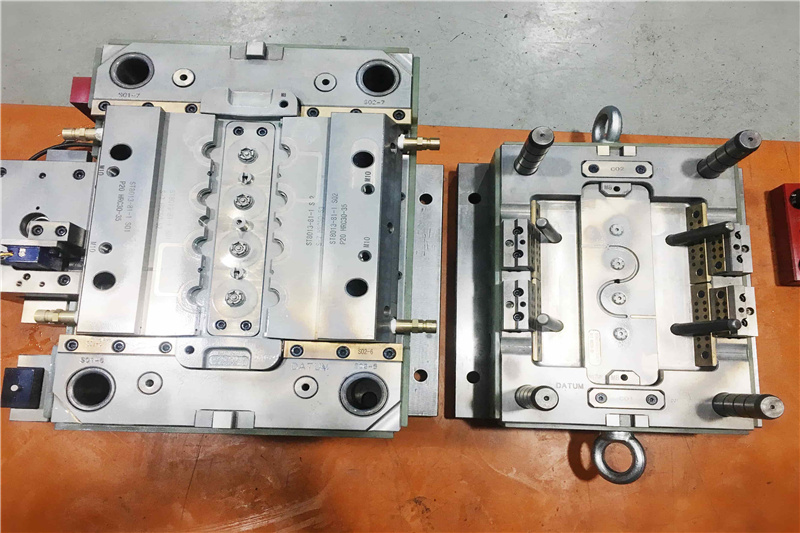

The injection mould tool is auto-unscrewing by motor and gear wheel. There are many insulation plates in mould four sides as the mold temperature is very high. This 4 cavity mold has moulding cycle time 39 seconds and the part tolerance is less than +/-0.02mm.

1. How is the mold temperature for this PPSU mold?

The mold temperature is 160~180 degree.

2.How about the tolerance for parts made in Suntime Precision Mould?

Mold: +_0.01mm, Plastic Part: +_0.02mm and Machining product: +_0.005mm.

3. What production material you usually use?

For plastic injection molding, resin includes PPSU, PEEK, ABS, PC, PC+ABS, PMMA, PP, HIPS, PE(HDPE,MDPE,LDPE). PA12, PA66, PA66+Glass fiber,TPE,TPR,TPU, PPSU, LCP, POM, PVDF, PET, PBT… And for die casting, the aluminum material is A380,A356,6061.

4. What is your design lead time?

“DFM: Normally Within 2 working day.

2D mold layout: Normally Within 3-4 working day.

3D mold drawing: Normally Within 4-5 working day.”

5. What regions is Suntime located?

Our factory is located in Chang An town of Dong Guan City in south of China, which is initial mold manufacturing place. 10 minutes to Shen Zhen. 30 minutes to Shen Zhen airport.

6. How’s your Communication skill?

“a). Rich experienced sales and engineers follow project and communicate in skilled English.

b). 24/7 style service. One to one project management.

c). Come to visit anytime and Suntime team visit customers yearly.

d). weekly report every Monday. (2 reports a week if needed).

e). Any emails reply within 24 hours, you can call us anytime, even in middle night. “

Product detail pictures:

Related Product Guide:

In order to best meet client's needs, all of our operations are strictly performed in line with our motto "High Quality, Competitive Price, Fast Service" for Quality Inspection for Pharmaceuticals Plastic Injection Moulder - Auto unscrewing mould making & High temperature mold PPSU material – Suntime, The product will supply to all over the world, such as: Zambia, Saudi Arabia, Austria, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

-

8 Year Exporter Telecommunications Metal Machin...

-

Factory Price For Plastic Injection Mould For C...

-

Factory Price For Plastic Injection Mould For C...

-

Big Discount Furniture Industry Plastic Accesso...

-

High Quality Cnc Machining For Iot Industry - ...

-

Hot sale China Mold Making - Custom Injection ...