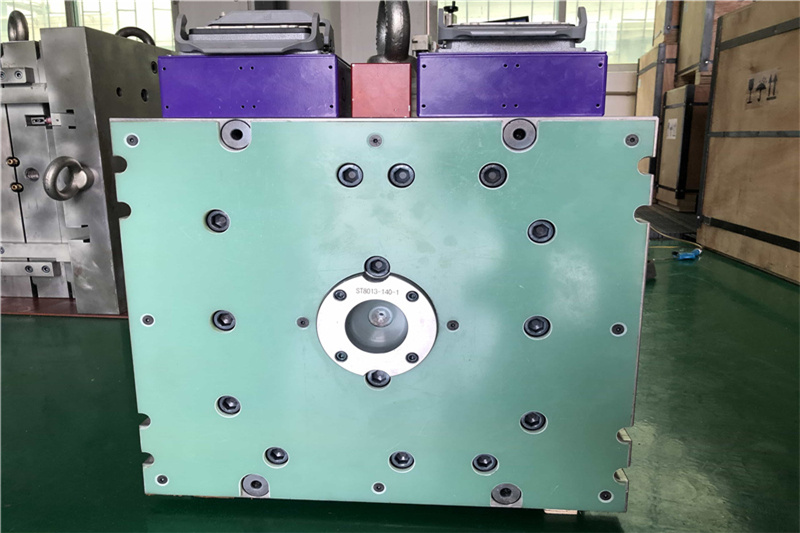

Real direct manufacturer of Tooling And Molding – Injection multi cavity mould for caps of packaging industry – Suntime Detail:

This is 16 cavity mould, mould delivery after T1, finished in very short time. Because the inside thread needs to be released by force, we need to make sure there is no scratch mark when demolding and assure the filling is balance. The hot runner is 16pcs hot tips of master tip.

| Appliance and Type | Package, bottle caps | |||||

| Part name | queen_cap | |||||

| Resin | PP | |||||

| No. of cavity | 1*16 | |||||

| Mould Base | DME 7# Equal /(AISI 420H) | |||||

| Steel of cavity&Core | S136 HRC48-50 | |||||

| Tool weight | 613KG | |||||

| Tool size | 369X515X510 | |||||

| Press Ton | T160 | |||||

| Mold life | 1000000 Shots | |||||

| Injection system | 16 Drop hot runner | |||||

| Cooling system | 25 ℃ | |||||

| Ejection System | Stripper Plate | |||||

| Special points | Multi cavity mold with 16 cavities, thread demold by force , mold ship after T1 | |||||

| Difficulties | No scratch mark when mold release by force, keep filling balance, short lead time | |||||

| Lead time | 4.5 weeks | |||||

| Package | Anti-rust Paper and film, little anti-rust oil and plywood box | |||||

| Packing items | Certification of steel, final 2D & 3D tool design, hot runner document, spare parts and electrodes… | |||||

| Shrinkage | 1.016 | |||||

| Surface finish | B-2 | |||||

| Trade terms | FOB Shenzhen | |||||

| Export to | Australia | |||||

Suntime has very effective mold designers. For DFM, it can be finished within 1~2 days, 2D layout within 2~4 days, and 3D within 3~5 days depending on mold complexity. When time is very urgent, we normally make 3D drawing directly after DFM, but of course, it must be based on customers’ approval.

DFM Analysis

DFM Analysis

3D mould design

3D mould design

1. How many molds Suntime Precision Mould can make every year?

150-220 sets of molds. (depends on the size and complexity)

2. What are the industries involved in your products?

Automotive, IoT, Telecommunication, Building, Industrial, Household appliance, Electronic, Packaging, Medical,…

3.What hot runner system do you use?

Yudo, Moldmaster, Incoe, Syventive, Masterflow, Mastertip,Husky…

4. I don’t have part drawings, how can I make quote?

You can take photos of this part showing the structure, and give us the rough dimension of width, length, height and so on. Or, you can send us the samples. We will scan the part and make part 2D & 3D drawings. After your confirmation of the part design, we will start the mold design process.

5. Do you have any Value added service?

“Yes, we have. Except mold making and custom injection molding. We also can provide service:

a). Silicon compression parts.

b). Metal stamping parts (Progressive Die ).

c). Plastic extrusion parts.

d). Die casting second machining and surface treatment (bead-blasting,anodizing…)

e). Plastic and Metal prototypes.

f). Mold design and engineering service. (24/7 communication services & technical support.)”

6. Do you accept small batch production?

Yes,we have 7 injection machines from 90 ton to 400 ton. We accept production from 1pcs to very big volumn.

Product detail pictures:

Related Product Guide:

The incredibly abundant projects administration experiences and 1 to one provider model make the superior importance of small business communication and our easy understanding of your expectations for Real direct manufacturer of Tooling And Molding – Injection multi cavity mould for caps of packaging industry – Suntime, The product will supply to all over the world, such as: Iran , Peru , Provence , Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,